Market Share

Aircraft Docking Systems Market Share Analysis

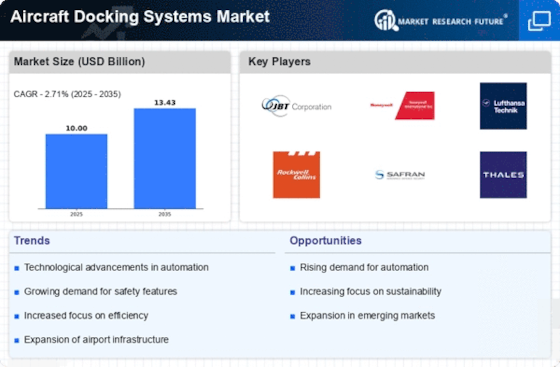

The Aircraft Docking Systems market is significantly influenced by various factors that shape its dynamics and growth. One of the primary factors driving market demand is the continuous expansion of the global aviation industry. With the increasing demand for air travel and the growing fleet of commercial and cargo aircraft, there is a parallel need for efficient maintenance, repair, and overhaul (MRO) services. Aircraft docking systems play a crucial role in facilitating safe and efficient maintenance operations by providing secure access to aircraft for inspection, servicing, and repair. As airlines and MRO facilities strive to optimize turnaround times, minimize downtime, and ensure operational safety, there is a growing demand for advanced aircraft docking systems that offer flexibility, adaptability, and scalability. This demand is a significant driver of market growth and investment in the Aircraft Docking Systems segment.

Moreover, technological advancements play a vital role in shaping the Aircraft Docking Systems market. Continuous innovation in materials science, structural engineering, and automation technologies enables the development of more advanced and feature-rich aircraft docking systems. Manufacturers invest in research and development to enhance the design, functionality, and safety features of docking systems, making them more adaptable to various aircraft types and configurations. For example, the integration of modular components, adjustable platforms, and computerized control systems enables aircraft docking systems to accommodate different aircraft models and sizes, reducing setup time and labor costs. Additionally, advancements in sensor technology and robotics enable automated docking procedures, improving operational efficiency and reducing the risk of human error. These technological advancements drive market innovation and propel the development of next-generation aircraft docking systems.

Furthermore, regulatory requirements and safety standards influence the dynamics of the Aircraft Docking Systems market. Aviation authorities such as the Federal Aviation Administration (FAA) and the European Union Aviation Safety Agency (EASA) establish guidelines, regulations, and certification requirements for aircraft maintenance equipment, including docking systems, to ensure their safety, reliability, and compliance with regulatory standards. Manufacturers must adhere to stringent design and testing procedures to obtain certification for docking systems, demonstrating their structural integrity, load-bearing capacity, and compatibility with different aircraft types. Additionally, industry organizations such as the International Air Transport Association (IATA) and the International Civil Aviation Organization (ICAO) develop technical standards and best practices for aircraft maintenance operations, including aircraft docking procedures. Compliance with regulatory requirements and industry standards is essential for market acceptance and adoption of Aircraft Docking Systems.

Moreover, market trends such as the increasing adoption of digital technologies and automation drive market growth and innovation in the Aircraft Docking Systems segment. With the proliferation of digital twin technology, augmented reality, and remote monitoring solutions, there is a growing interest in digitizing aircraft maintenance operations and optimizing workflow efficiency. Digital twin technology enables virtual modeling and simulation of aircraft structures and systems, facilitating proactive maintenance planning and predictive maintenance strategies. Augmented reality (AR) applications provide technicians with real-time guidance and visualizations during maintenance tasks, improving productivity and reducing errors. Additionally, remote monitoring solutions enable MRO facilities to monitor the status and performance of aircraft docking systems remotely, optimizing resource allocation and scheduling. These digitalization trends drive market demand for Aircraft Docking Systems that support digital integration and automation capabilities.

Furthermore, market competitiveness and industry consolidation influence market dynamics in the Aircraft Docking Systems segment. With a limited number of established manufacturers and suppliers specializing in aircraft maintenance equipment, competition intensifies, leading to consolidation and strategic partnerships within the industry. Market leaders invest in research and development, technology innovation, and manufacturing capabilities to maintain their competitive edge and win lucrative contracts with airlines and MRO facilities. Additionally, mergers, acquisitions, and joint ventures enable companies to expand their market presence, diversify their product portfolios, and access new markets. Collaboration with aircraft manufacturers, airlines, and industry stakeholders further enhances market competitiveness and drives innovation in Aircraft Docking Systems technology.

Moreover, economic factors such as airline profitability, fleet expansion, and MRO spending impact market demand for Aircraft Docking Systems. Airlines and MRO facilities evaluate the total cost of ownership, including acquisition costs, maintenance expenses, and operational benefits when investing in aircraft maintenance equipment. Economic downturns, fluctuating fuel prices, and geopolitical uncertainties may influence investment decisions and budget allocations for aircraft maintenance projects. Additionally, airlines prioritize investments in docking systems that offer flexibility, scalability, and compatibility with their existing fleet and operational requirements. By understanding and addressing these economic factors, manufacturers, suppliers, and stakeholders can capitalize on market opportunities and drive sustainable growth in the Aircraft Docking Systems segment.

Leave a Comment