Market Trends

Key Emerging Trends in the Aircraft Docking Systems Market

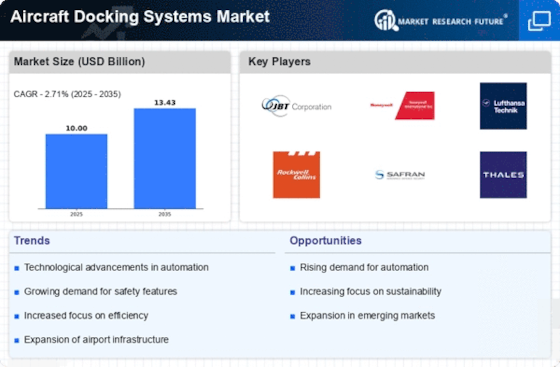

The Aircraft Docking Systems market is influenced by a myriad of dynamic market dynamics that shape its growth and evolution. One of the primary drivers of this market is the increasing demand for aircraft maintenance, repair, and overhaul (MRO) services driven by the expanding global aviation industry. With the growing fleet of commercial and military aircraft worldwide, there is a corresponding need for efficient and reliable docking systems to facilitate routine maintenance, inspections, and repairs. Aircraft docking systems provide critical support structures for technicians and engineers working on aircraft, ensuring safety, accessibility, and operational efficiency during maintenance activities. Consequently, the rising demand for MRO services drives market growth in the aircraft docking systems segment.

Moreover, technological advancements and innovations play a significant role in shaping market trends in the aircraft docking systems segment. Manufacturers are continually developing new and improved docking systems equipped with advanced features such as adjustable platforms, telescopic gangways, integrated lighting, and automated positioning systems. These technological innovations enhance the versatility, usability, and safety of aircraft docking systems, enabling more efficient and effective maintenance operations. Additionally, the integration of digital technologies, such as augmented reality (AR) and virtual reality (VR), into docking systems provides technicians with enhanced visualization tools and training capabilities, further driving market demand.

Furthermore, market factors such as regulatory requirements and safety standards influence market dynamics in the aircraft docking systems segment. Regulatory bodies, such as the Federal Aviation Administration (FAA) and the European Union Aviation Safety Agency (EASA), impose strict certification requirements and guidelines for aircraft maintenance facilities and equipment to ensure airworthiness and safety. Manufacturers must comply with these regulations and obtain necessary certifications for their docking systems to be used in commercial aviation. Additionally, adherence to industry standards, such as those set by the International Air Transport Association (IATA) and the International Civil Aviation Organization (ICAO), drives innovation and quality assurance in docking system design and manufacturing.

Additionally, the growth of the global aviation industry and the increasing number of aircraft deliveries contribute to market expansion in the aircraft docking systems segment. With rising passenger demand and fleet expansion plans by airlines and military organizations worldwide, the demand for MRO services and associated equipment, including docking systems, continues to rise. Aircraft manufacturers are experiencing an uptick in orders for new aircraft, which in turn drives demand for docking systems to support maintenance operations. Moreover, the emergence of new aircraft programs and the introduction of next-generation aircraft models stimulate market growth as manufacturers seek innovative solutions to meet evolving market demands.

Furthermore, market competitiveness and industry consolidation shape market dynamics in the aircraft docking systems segment. With several established players and emerging manufacturers competing for market share, competition intensifies, leading to innovation, product differentiation, and pricing strategies. Market leaders invest in research and development to stay ahead of the competition, introduce new technologies, and expand their product portfolios. Additionally, mergers, acquisitions, and strategic partnerships enable companies to strengthen their market position, enhance their capabilities, and access new markets, driving market consolidation and shaping industry dynamics.

Leave a Comment