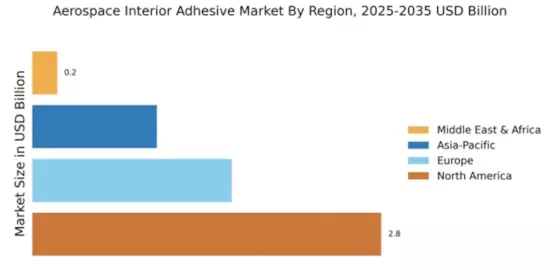

Market Growth Visualization

The Global Aerospace Interior Adhesive Market Industry is poised for substantial growth, with projections indicating a rise from 5.6 USD Billion in 2024 to 8.33 USD Billion by 2035. The anticipated CAGR of 3.67% from 2025 to 2035 underscores the industry's resilience and adaptability in response to evolving market dynamics. This growth trajectory is influenced by various factors, including technological advancements, regulatory compliance, and increasing aircraft production rates. Visualizing this market growth through charts can provide valuable insights into trends and opportunities within the aerospace adhesive sector.

Increasing Aircraft Production Rates

Increasing aircraft production rates are a key driver in the Global Aerospace Interior Adhesive Market Industry. The resurgence of air travel and the expansion of airline fleets have led to heightened demand for new aircraft. This trend is particularly pronounced in emerging markets, where rising disposable incomes and urbanization fuel the need for air transportation. As manufacturers ramp up production to meet this demand, the requirement for high-quality adhesives in aircraft interiors becomes more pronounced. This surge in production is likely to bolster the market, aligning with the anticipated growth trajectory over the coming years.

Focus on Sustainable Aviation Practices

The focus on sustainable aviation practices is reshaping the Global Aerospace Interior Adhesive Market Industry. Airlines and manufacturers are increasingly prioritizing eco-friendly materials and processes to minimize their environmental impact. This shift is evident in the adoption of bio-based adhesives that reduce reliance on petroleum-derived products. As sustainability becomes a core component of corporate strategies, the demand for innovative adhesive solutions that align with these practices is expected to rise. This trend not only enhances the market's growth potential but also reflects a broader commitment to environmental stewardship within the aerospace sector.

Growing Demand for Lightweight Materials

The Global Aerospace Interior Adhesive Market Industry experiences a growing demand for lightweight materials as manufacturers strive to enhance fuel efficiency and reduce emissions. The integration of advanced adhesive solutions allows for the use of lighter materials in aircraft interiors, which contributes to overall weight reduction. This trend is particularly evident in the commercial aviation sector, where airlines are increasingly adopting lightweight designs to comply with stringent environmental regulations. As a result, the market is projected to reach 5.6 USD Billion in 2024, reflecting the industry's shift towards innovative materials that support sustainability goals.

Regulatory Compliance and Safety Standards

Regulatory compliance and safety standards significantly influence the Global Aerospace Interior Adhesive Market Industry. Stringent regulations imposed by aviation authorities necessitate the use of high-performance adhesives that meet specific safety criteria. For example, the Federal Aviation Administration (FAA) mandates rigorous testing for materials used in aircraft interiors to ensure passenger safety. This regulatory landscape compels manufacturers to invest in advanced adhesive technologies that comply with these standards. Consequently, the market is anticipated to expand as companies prioritize safety and compliance, contributing to the projected growth to 8.33 USD Billion by 2035.

Technological Advancements in Adhesive Formulations

Technological advancements in adhesive formulations play a pivotal role in the Global Aerospace Interior Adhesive Market Industry. Innovations in chemical compositions and application techniques enhance the performance and durability of adhesives used in aircraft interiors. For instance, the development of high-temperature resistant adhesives ensures that materials maintain their integrity under extreme conditions. These advancements not only improve safety but also extend the lifespan of aircraft interiors, thereby reducing maintenance costs. As the industry evolves, the market is expected to grow at a CAGR of 3.67% from 2025 to 2035, driven by continuous research and development efforts.