Aerospace Fasteners Market Summary

As per Market Research Future analysis, the Aerospace Fasteners Market Size was estimated at 5.964 USD Billion in 2024. The Global Aerospace Fasteners market is projected to grow from 6.934 USD Billion in 2025 to 31.28 USD Billion by 2035, exhibiting a compound annual growth rate (CAGR) of 16.26% during the forecast period 2025 - 2035.

Key Market Trends & Highlights

The Aerospace Fasteners Market is poised for growth driven by technological advancements and increasing demand for lightweight materials.

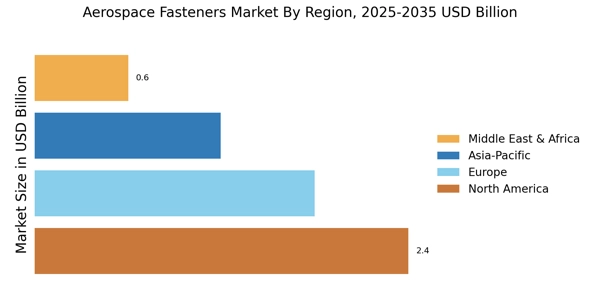

- The market is experiencing a notable shift towards lightweight materials, particularly in the North American region.

- Sustainability is becoming a focal point, influencing design and manufacturing processes across the industry.

- Automation in manufacturing processes is gaining traction, enhancing efficiency and precision in fastener production.

- The increasing demand for commercial aircraft and advancements in fastener design are key drivers propelling market growth, especially in the Asia-Pacific region.

Market Size & Forecast

| 2024 Market Size | 5.964 (USD Billion) |

| 2035 Market Size | 31.28 (USD Billion) |

| CAGR (2025 - 2035) | 16.26% |

Major Players

Boeing (US), Lockheed Martin (US), Raytheon Technologies (US), Northrop Grumman (US), Airbus (FR), Safran (FR), General Electric (US), Honeywell (US), LISI Aerospace (FR), Triumph Group (US)