Market Trends

Key Emerging Trends in the Acrylic Surface Coating Market

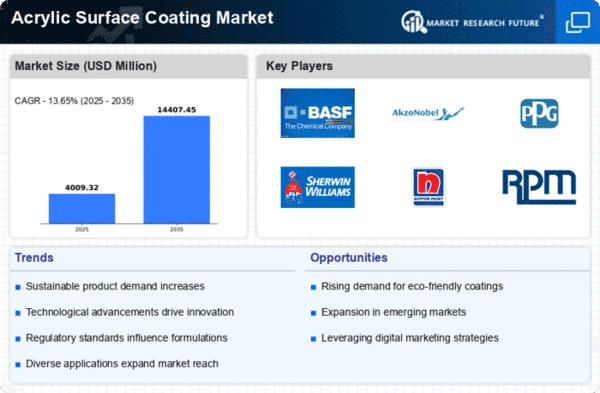

The acrylic surface coating market has been experiencing notable trends in recent years, driven by various factors such as technological advancements, changing consumer preferences, and environmental regulations. One prominent trend in the market is the increasing demand for eco-friendly acrylic coatings. As awareness about environmental sustainability grows, consumers and industries alike are seeking coatings that have minimal impact on the environment. This has led to a surge in the development and adoption of water-based acrylic coatings, which contain lower levels of volatile organic compounds (VOCs) compared to traditional solvent-based coatings. Manufacturers are investing heavily in research and development to formulate acrylic coatings that offer high performance while also meeting stringent environmental standards.

The growing demand for acrylic protective coatings on the industrial tools and equipment and decorative parts.

Another key trend shaping the acrylic surface coating market is the growing emphasis on durability and longevity. Consumers are increasingly seeking coatings that can withstand harsh weather conditions, UV radiation, and chemical exposure, particularly in outdoor applications such as automotive coatings, architectural coatings, and industrial coatings. As a result, there has been a rising demand for acrylic coatings that offer enhanced durability, scratch resistance, and color retention properties. Manufacturers are responding to this trend by introducing innovative formulations that incorporate advanced additives and nanotechnology to improve the overall performance of acrylic coatings.

Additionally, the market for acrylic surface coatings is witnessing a shift towards customization and personalization. With the rise of digital printing technologies and the growing trend towards individualization, consumers are seeking coatings that can be easily customized to meet their specific design preferences and requirements. This has led to the development of acrylic coatings that offer a wide range of colors, textures, and finishes, allowing consumers to create unique and personalized surfaces for various applications. From decorative paints and coatings for interior walls to custom finishes for automotive components, the demand for customizable acrylic coatings is on the rise across diverse end-use industries.

Furthermore, the acrylic surface coating market is experiencing significant growth in emerging economies, driven by rapid urbanization, industrialization, and infrastructure development. Countries in Asia-Pacific, Latin America, and the Middle East are witnessing robust demand for acrylic coatings in construction, automotive, and manufacturing sectors, as they continue to invest in new infrastructure projects and expand their industrial base. Moreover, rising disposable incomes and changing lifestyle preferences are fueling the demand for premium acrylic coatings in these regions, as consumers seek high-quality finishes for their homes, vehicles, and consumer goods.

Leave a Comment