Market Analysis

In-depth Analysis of Acrylic Surface Coating Market Industry Landscape

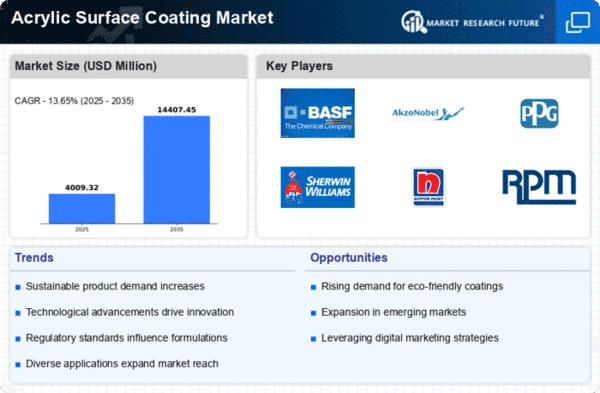

The acrylic surface coating market is driven by various market dynamics that influence its growth and demand. These dynamics include factors such as industry trends, consumer preferences, technological advancements, regulatory policies, and competitive landscape.

One of the primary drivers of the acrylic surface coating market is the growing construction and infrastructure sector. With rapid urbanization and industrialization, there is an increasing demand for coatings that can protect and enhance the appearance of various surfaces such as concrete, metal, wood, and plastics. Acrylic coatings offer excellent durability, weather resistance, and aesthetic appeal, making them popular choices for architectural coatings, protective coatings, and decorative finishes in both residential and commercial construction projects.

The increasing demand for metal substrate acrylic coatings to protect the metal surface from rusting.

Another key factor driving the market is the rising awareness about environmental sustainability and the shift towards eco-friendly coating solutions. Acrylic coatings are known for their low VOC (volatile organic compound) content and water-based formulations, which make them less harmful to the environment and human health compared to solvent-based coatings. As governments around the world implement stricter regulations to reduce air pollution and promote sustainable practices, the demand for acrylic surface coatings is expected to increase further.

Technological advancements play a significant role in shaping the acrylic surface coating market dynamics. Manufacturers are constantly innovating to develop new formulations with improved performance characteristics such as faster drying times, enhanced adhesion, better UV resistance, and superior scratch resistance. These advancements enable acrylic coatings to meet the evolving needs of end-users across various industries, including automotive, aerospace, marine, and industrial manufacturing.

Market dynamics also include changes in consumer preferences and lifestyle trends. As consumers become more discerning and design-conscious, there is a growing demand for coatings that offer customizable colors, textures, and finishes to achieve desired aesthetic effects. Acrylic coatings can be easily tinted and blended to create a wide range of colors and effects, making them versatile options for interior and exterior applications in residential and commercial settings.

Furthermore, the competitive landscape of the acrylic surface coating market is influenced by factors such as industry consolidation, mergers and acquisitions, and strategic partnerships. Large multinational corporations dominate the market, leveraging their extensive distribution networks, research and development capabilities, and brand reputation to gain a competitive edge. However, there is also a significant presence of small and medium-sized enterprises (SMEs) that specialize in niche segments or regional markets, offering innovative solutions and personalized services to cater to specific customer needs.

Leave a Comment