Advancements in Cable Technology

Technological innovations are reshaping the Wire Cable Polymer Market, with advancements in cable technology leading to enhanced performance and reliability. The introduction of new polymer materials and manufacturing techniques is enabling the production of lighter, more flexible, and durable cables. These innovations are particularly relevant in sectors such as telecommunications and construction, where high-performance cables are essential. Market analysts suggest that the adoption of these advanced technologies could result in a market expansion of approximately 5% annually. As industries increasingly prioritize efficiency and performance, the Wire Cable Polymer Market is poised for growth driven by these technological advancements.

Rising Demand for Renewable Energy

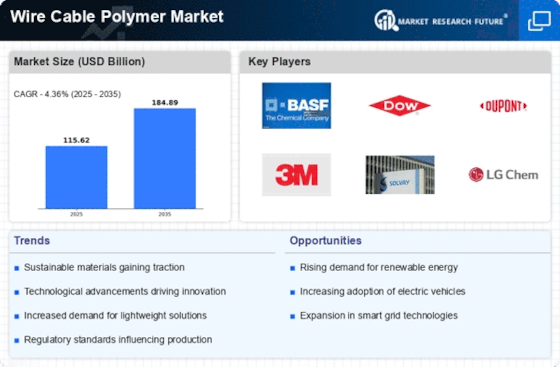

The Wire Cable Polymer Market is experiencing a notable surge in demand due to the increasing focus on renewable energy sources. As countries strive to meet energy transition goals, the need for efficient and durable wire cables becomes paramount. For instance, the installation of solar panels and wind turbines necessitates high-performance cables that can withstand environmental stressors. This trend is projected to drive the market, with estimates suggesting a compound annual growth rate of approximately 6% over the next five years. The shift towards sustainable energy solutions is likely to bolster the Wire Cable Polymer Market, as manufacturers innovate to meet the specific requirements of renewable energy applications.

Increased Focus on Safety Standards

The Wire Cable Polymer Market is also influenced by the heightened emphasis on safety standards across various sectors. Regulatory bodies are implementing stricter guidelines regarding the materials and performance of wire cables, particularly in industries such as construction and automotive. This focus on safety is driving manufacturers to invest in higher-quality polymers that meet or exceed these standards. As a result, the market is likely to see a shift towards more resilient and fire-resistant cable solutions. Analysts predict that compliance with these evolving safety regulations could lead to a market growth rate of around 4% annually, reflecting the industry's commitment to safety and quality.

Growth in Electric Vehicle Production

The Wire Cable Polymer Market is significantly influenced by the burgeoning electric vehicle (EV) sector. As automotive manufacturers ramp up production to meet consumer demand for EVs, the requirement for specialized wire cables is escalating. These cables must not only support high voltage but also ensure safety and efficiency. Recent data indicates that the EV market is expected to grow at a staggering rate, potentially reaching over 30 million units sold annually by 2030. This growth is likely to create substantial opportunities for the Wire Cable Polymer Market, as manufacturers adapt their offerings to cater to the unique needs of electric vehicles.

Infrastructure Development Initiatives

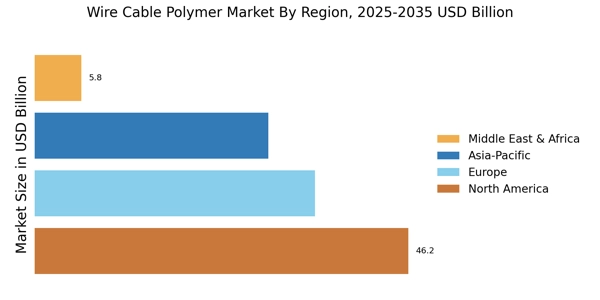

The Wire Cable Polymer Market is benefiting from extensive infrastructure development initiatives across various regions. Governments are investing heavily in upgrading transportation networks, utilities, and communication systems, which necessitates the use of high-quality wire cables. For example, the construction of smart cities and the expansion of broadband networks require robust wiring solutions that can support advanced technologies. Recent reports indicate that infrastructure spending is projected to increase by 10% over the next few years, creating a favorable environment for the Wire Cable Polymer Market. This trend underscores the critical role that wire cables play in modern infrastructure projects.