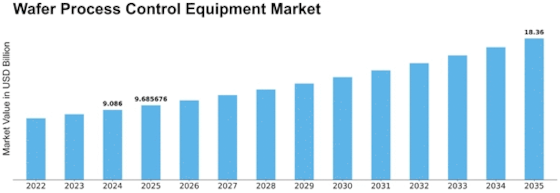

Wafer Process Control Equipment Size

Wafer Process Control Equipment Market Growth Projections and Opportunities

The Wafer Process Control Equipment market is influenced by a myriad of factors that collectively shape its dynamics and growth trajectory. One of the primary market drivers is the continuous evolution of semiconductor technology. As the semiconductor industry strives to keep pace with the ever-increasing demand for smaller, faster, and more efficient electronic devices, the need for advanced wafer process control equipment becomes paramount. The market is also significantly impacted by the global demand for consumer electronics, ranging from smartphones to smart appliances. As these devices become more integral to modern life, semiconductor manufacturers face heightened pressure to enhance production efficiency, driving the adoption of sophisticated process control equipment.

Moreover, the market's growth is intertwined with research and development activities in the semiconductor sector. Technological advancements and innovations in wafer processing techniques propel the demand for cutting-edge process control equipment. This includes tools and systems that offer higher precision, increased automation, and improved reliability in semiconductor fabrication. Collaborations between semiconductor manufacturers and equipment providers play a crucial role in fostering innovation, as industry players work together to address the challenges associated with scaling down semiconductor components.

Global economic conditions and geopolitical factors also exert a substantial influence on the Wafer Process Control Equipment market. Economic downturns can lead to reduced consumer spending on electronics, impacting semiconductor demand and, consequently, the need for process control equipment. Additionally, geopolitical tensions and trade policies can disrupt the global supply chain, affecting the production and distribution of semiconductor-related equipment. Uncertainties in these areas can create challenges for market players, necessitating strategic adaptability to navigate fluctuations in demand and supply.

Environmental considerations contribute to shaping the market dynamics as well. The semiconductor industry is under increasing scrutiny regarding its environmental impact, prompting a growing emphasis on sustainable and eco-friendly practices. This has led to the development and adoption of wafer process control equipment that minimizes resource consumption, reduces waste, and complies with stringent environmental regulations. As sustainability becomes a more significant factor in purchasing decisions, manufacturers are compelled to incorporate environmentally friendly features into their equipment to stay competitive in the market.

Furthermore, the market is subject to the influence of regulatory frameworks governing the semiconductor industry. Changes in regulations related to safety standards, intellectual property rights, and export controls can have a profound impact on market dynamics. Compliance with these regulations is crucial for market players to ensure smooth operations and avoid legal challenges.

Lastly, the ever-growing trend of digital transformation across industries contributes to the market's expansion. Industries such as automotive, healthcare, and telecommunications are increasingly reliant on semiconductor components, driving the demand for advanced wafer process control equipment. The integration of semiconductor technology into diverse applications underscores the market's potential for sustained growth, as industries leverage the capabilities of cutting-edge electronics to enhance their products and services.

Leave a Comment