Growth in Emerging Markets

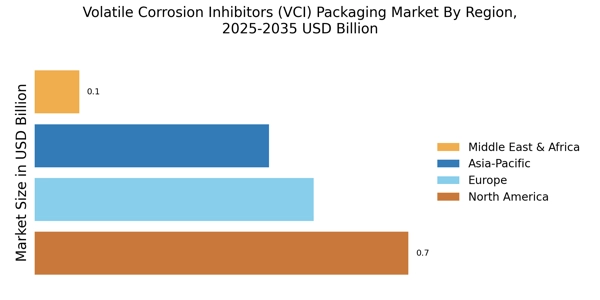

The Volatile Corrosion Inhibitors Vci Packaging Market is poised for growth in emerging markets, where industrialization and infrastructure development are accelerating. Countries in Asia-Pacific, Latin America, and parts of Africa are experiencing rapid economic growth, leading to increased investments in manufacturing and construction sectors. This growth is accompanied by a rising demand for effective corrosion protection solutions to safeguard investments in machinery and equipment. As industries expand in these regions, the need for VCI packaging solutions is likely to rise, driven by the necessity to protect assets from corrosion during transit and storage. Market analysts suggest that the expansion of manufacturing capabilities in these emerging economies could lead to a significant increase in the adoption of VCI technologies, thereby propelling the overall market forward.

Regulatory Compliance and Standards

The Volatile Corrosion Inhibitors Vci Packaging Market is significantly influenced by stringent regulatory compliance and standards aimed at reducing environmental impact. Governments and regulatory bodies are increasingly mandating the use of eco-friendly packaging materials that minimize corrosion while adhering to safety and environmental guidelines. This trend is particularly evident in industries such as manufacturing and shipping, where compliance with regulations can lead to substantial cost savings and improved operational efficiency. The adoption of VCI packaging solutions not only meets these regulatory requirements but also enhances the overall sustainability of operations. As a result, companies are likely to invest in VCI technologies to ensure compliance and maintain a competitive edge in the market.

Rising Demand for Corrosion Protection

The Volatile Corrosion Inhibitors Vci Packaging Market is experiencing a notable increase in demand for effective corrosion protection solutions. Industries such as automotive, aerospace, and electronics are increasingly recognizing the importance of safeguarding their products from corrosion during storage and transportation. This heightened awareness is driven by the need to reduce maintenance costs and extend the lifespan of equipment. According to recent estimates, the corrosion protection market is projected to grow at a compound annual growth rate of approximately 5.5% over the next few years. As a result, the demand for VCI packaging solutions is expected to rise, as they offer a reliable and efficient means of protecting metal components from corrosion, thereby enhancing product durability and reliability.

Technological Innovations in VCI Solutions

The Volatile Corrosion Inhibitors Vci Packaging Market is witnessing a surge in technological innovations that enhance the effectiveness of VCI solutions. Advances in material science and chemistry have led to the development of more efficient and longer-lasting VCI formulations. These innovations enable manufacturers to create packaging that provides superior corrosion protection while being lightweight and cost-effective. Furthermore, the integration of smart technologies, such as sensors and monitoring systems, into VCI packaging is becoming increasingly prevalent. This allows for real-time tracking of environmental conditions, ensuring optimal protection for sensitive products. As these technological advancements continue to evolve, they are likely to drive the growth of the VCI packaging market, as companies seek to leverage these innovations to improve product quality and reduce losses due to corrosion.

Increased Focus on Product Quality and Longevity

The Volatile Corrosion Inhibitors Vci Packaging Market is increasingly influenced by the growing emphasis on product quality and longevity. Manufacturers across various sectors are recognizing that corrosion can severely impact the performance and lifespan of their products. As a result, there is a concerted effort to implement packaging solutions that not only protect against corrosion but also enhance the overall quality of the product. This trend is particularly evident in high-value industries such as electronics and automotive, where even minor corrosion can lead to significant financial losses. The adoption of VCI packaging solutions is seen as a proactive measure to ensure that products remain in optimal condition throughout their lifecycle. Consequently, this focus on quality and longevity is likely to drive demand for VCI technologies, as companies strive to meet consumer expectations and maintain their market position.