Rising Demand for PVC Products

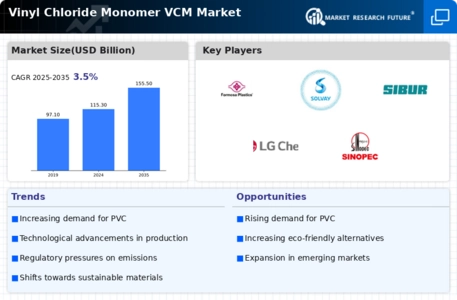

The Vinyl Chloride Monomer Market VCM Market is experiencing a notable increase in demand for polyvinyl chloride (PVC) products. PVC is widely utilized in construction, automotive, and consumer goods due to its durability and versatility. The construction sector, in particular, is a significant driver, as PVC is employed in pipes, windows, and flooring. According to recent data, the demand for PVC is projected to grow at a compound annual growth rate (CAGR) of approximately 4.5% over the next few years. This surge in demand for PVC products directly influences the Vinyl Chloride Monomer Market VCM Market, as VCM is the primary raw material for PVC production. Consequently, manufacturers are likely to increase VCM production to meet this rising demand.

Expansion of End-Use Industries

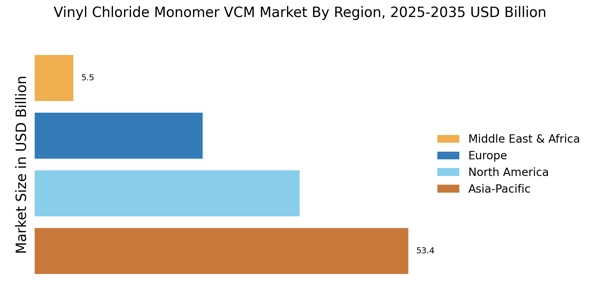

The Vinyl Chloride Monomer Market VCM Market is benefiting from the expansion of various end-use industries, particularly in construction and automotive sectors. As urbanization continues to rise, the demand for construction materials, including PVC, is expected to increase. Additionally, the automotive industry is increasingly utilizing PVC for interior and exterior applications due to its lightweight and durable properties. Market data suggests that the construction sector alone accounts for over 60% of the total PVC consumption, which directly impacts the demand for VCM. This expansion in end-use industries is likely to sustain the growth trajectory of the Vinyl Chloride Monomer Market VCM Market, as manufacturers strive to meet the evolving needs of these sectors.

Growing Environmental Regulations

The Vinyl Chloride Monomer Market VCM Market is currently navigating a landscape shaped by stringent environmental regulations. Governments are increasingly implementing policies aimed at reducing emissions and promoting sustainable practices. These regulations often necessitate the adoption of cleaner production methods and the use of environmentally friendly materials. As a result, manufacturers in the Vinyl Chloride Monomer Market VCM Market are compelled to innovate and invest in technologies that align with these regulations. This shift not only enhances the sustainability of VCM production but also opens up new market opportunities for companies that can meet these regulatory requirements. The potential for penalties and the need for compliance are likely to drive significant changes in production practices.

Innovations in Production Technologies

Technological advancements in the production processes of Vinyl Chloride Monomer Market VCM Market are playing a crucial role in enhancing efficiency and reducing costs. Innovations such as the development of more efficient catalytic processes and the integration of automation in manufacturing are becoming increasingly prevalent. These advancements not only improve the yield of VCM but also minimize waste and energy consumption. For instance, recent studies indicate that new production technologies can reduce energy usage by up to 20%, which is significant in an industry where operational costs are critical. As manufacturers adopt these technologies, the overall competitiveness of the Vinyl Chloride Monomer Market VCM Market is likely to improve, attracting further investments.

Increasing Investment in Infrastructure Development

The Vinyl Chloride Monomer Market VCM Market is poised to benefit from rising investments in infrastructure development across various regions. Governments are prioritizing infrastructure projects to stimulate economic growth, which includes the construction of roads, bridges, and residential buildings. Such projects often require substantial amounts of PVC for pipes, fittings, and other construction materials. Recent forecasts indicate that infrastructure spending is expected to grow significantly, with estimates suggesting an increase of over 5% annually in the coming years. This trend is likely to create a robust demand for Vinyl Chloride Monomer Market, as it is essential for producing the PVC used in these infrastructure projects. Consequently, the Vinyl Chloride Monomer Market VCM Market is expected to experience sustained growth driven by these investments.