Diverse Application Range

The Global Vinyl Acetate Homopolymer Emulsion Market Industry benefits from its diverse application range across multiple sectors. These emulsions are utilized in adhesives, paints, coatings, textiles, and paper products, showcasing their versatility. The ability to adapt to various formulations allows manufacturers to meet specific industry requirements effectively. As industries continue to evolve, the demand for high-performance emulsions is likely to increase, further driving market growth. This broad applicability positions vinyl acetate homopolymer emulsions as a fundamental component in numerous products, ensuring their sustained relevance in the global market.

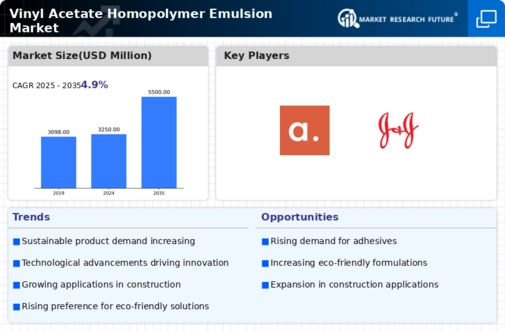

Market Growth Projections

The Global Vinyl Acetate Homopolymer Emulsion Market Industry is poised for substantial growth, with projections indicating a market size of 3250 USD Million by 2024 and an anticipated increase to 5500 USD Million by 2035. This growth trajectory suggests a compound annual growth rate of 4.9% from 2025 to 2035, reflecting the increasing adoption of vinyl acetate homopolymer emulsions across various industries. The expanding applications, coupled with technological advancements and regulatory pressures, are likely to contribute to this upward trend. The market's resilience and adaptability to changing industry dynamics further reinforce its potential for sustained growth in the coming years.

Growth in Automotive Applications

The automotive industry is a notable driver for the Global Vinyl Acetate Homopolymer Emulsion Market Industry. These emulsions are increasingly employed in manufacturing automotive coatings and adhesives, which require high durability and performance. As the automotive sector shifts towards lightweight materials and eco-friendly solutions, vinyl acetate homopolymer emulsions are positioned to meet these evolving demands. The market is expected to witness a compound annual growth rate of 4.9% from 2025 to 2035, indicating a robust expansion driven by innovations in automotive technology and design. This trend underscores the versatility and adaptability of vinyl acetate emulsions in meeting industry-specific requirements.

Increasing Environmental Regulations

The Global Vinyl Acetate Homopolymer Emulsion Market Industry is influenced by the tightening of environmental regulations. Governments worldwide are enforcing stricter standards on volatile organic compounds (VOCs) in paints and coatings, prompting manufacturers to seek low-VOC alternatives. Vinyl acetate homopolymer emulsions are inherently lower in VOC content, making them an attractive option for compliance with these regulations. This shift not only enhances product safety but also aligns with the growing consumer preference for environmentally friendly products. As a result, the market is likely to benefit from increased adoption of these emulsions in various applications, reinforcing their role in sustainable development.

Rising Demand in Construction Sector

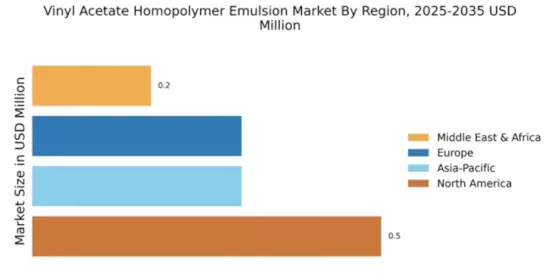

The Global Vinyl Acetate Homopolymer Emulsion Market Industry is experiencing a surge in demand driven by the construction sector. This emulsion is widely utilized in adhesives, paints, and coatings, which are essential for various construction applications. As urbanization continues to expand, particularly in developing regions, the need for durable and high-performance materials is paramount. The market is projected to reach 3250 USD Million by 2024, reflecting the increasing reliance on vinyl acetate homopolymer emulsions in construction. Furthermore, the anticipated growth in infrastructure projects globally suggests a sustained demand for these emulsions, reinforcing their significance in the construction landscape.

Technological Advancements in Production

Technological innovations in the production of vinyl acetate homopolymer emulsions are propelling the Global Vinyl Acetate Homopolymer Emulsion Market Industry forward. Advances in polymerization techniques and formulation technologies have led to the development of emulsions with enhanced properties, such as improved adhesion, flexibility, and weather resistance. These advancements enable manufacturers to cater to diverse applications across industries, including construction, automotive, and textiles. As the market evolves, the introduction of novel formulations is expected to drive growth, with projections indicating a market size of 5500 USD Million by 2035. This trajectory highlights the importance of continuous innovation in maintaining competitiveness within the industry.