US Waterborne Coatings Market Summary

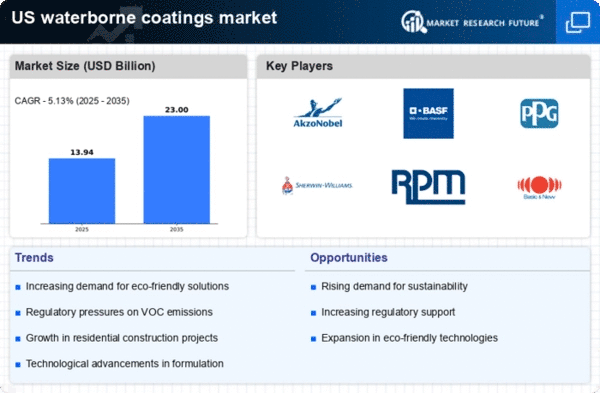

As per Market Research Future analysis, the US waterborne coatings market size was estimated at 13.26 USD Billion in 2024. The US waterborne coatings market is projected to grow from 13.94 USD Billion in 2025 to 23.0 USD Billion by 2035, exhibiting a compound annual growth rate (CAGR) of 5.1% during the forecast period 2025 - 2035

Key Market Trends & Highlights

The US The waterborne coatings market is shifting robustly towards sustainability and innovation.

- The market is increasingly driven by a focus on sustainability, with eco-friendly formulations gaining traction.

- Technological advancements are enhancing the performance and application of waterborne coatings across various sectors.

- The architectural segment remains the largest, while the industrial segment is identified as the fastest-growing in the market.

- Regulatory compliance pressure and rising demand for eco-friendly products are key drivers propelling market growth.

Market Size & Forecast

| 2024 Market Size | 13.26 (USD Billion) |

| 2035 Market Size | 23.0 (USD Billion) |

| CAGR (2025 - 2035) | 5.13% |

Major Players

AkzoNobel (NL), BASF (DE), PPG Industries (US), Sherwin-Williams (US), RPM International (US), Nippon Paint Holdings (JP), Henkel (DE), Valspar (US), Kansai Paint (JP)