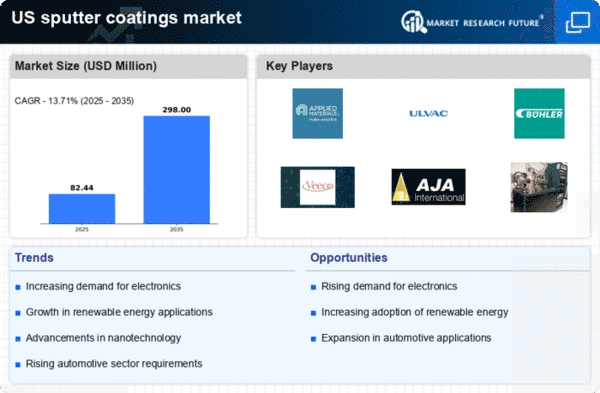

Rising Demand in Electronics

The sputter coatings market is experiencing a notable surge in demand driven by the electronics sector. As consumer electronics continue to evolve, manufacturers are increasingly utilizing sputter coatings for their superior properties, such as enhanced conductivity and durability. In 2025, the electronics industry is projected to account for approximately 30% of the total market share, reflecting a robust growth trajectory. This trend is particularly evident in the production of semiconductors and display technologies, where sputter coatings play a critical role in improving performance and efficiency. The increasing integration of advanced materials in electronic devices further propels the need for high-quality sputter coatings, thereby solidifying their importance in the sputter coatings market.

Advancements in Automotive Technologies

The automotive industry is undergoing a transformation with the rise of electric vehicles (EVs) and advanced driver-assistance systems (ADAS). This shift is positively impacting the sputter coatings market, as these technologies require high-performance coatings for components such as sensors and batteries. In 2025, the automotive sector is expected to represent approximately 20% of the market share. Sputter coatings provide essential properties such as thermal stability and corrosion resistance, which are crucial for the longevity and reliability of automotive components. As manufacturers continue to innovate, the demand for sputter coatings in automotive applications is likely to grow, further driving the sputter coatings market.

Growth in Renewable Energy Applications

The sputter coatings market is poised for growth due to the expanding applications in renewable energy technologies. Solar panels and wind turbines increasingly require sputter coatings to enhance their efficiency and longevity. In 2025, it is estimated that the renewable energy sector will contribute around 25% to the overall market demand. Sputter coatings are essential for improving the performance of photovoltaic cells and protecting components from environmental degradation. As the US government continues to promote clean energy initiatives, the demand for sputter coatings in this sector is likely to increase, indicating a promising outlook for the sputter coatings market.

Increased Focus on Research and Development

Investment in research and development (R&D) within the sputter coatings market is becoming increasingly vital. Companies are allocating significant resources to develop new materials and processes that enhance the performance of sputter coatings. This focus on innovation is expected to lead to the introduction of advanced coatings with superior properties, catering to diverse applications across various industries. In 2025, R&D expenditures in the sputter coatings market are projected to increase by approximately 15%, reflecting a commitment to technological advancement. This trend not only fosters competition but also drives the overall growth of the sputter coatings market.

Regulatory Compliance and Quality Standards

The sputter coatings market is influenced by stringent regulatory compliance and quality standards across various industries. As manufacturers strive to meet these requirements, the demand for high-quality sputter coatings is expected to rise. Industries such as aerospace, medical devices, and telecommunications are particularly affected by these regulations, necessitating the use of reliable coatings that adhere to safety and performance standards. In 2025, it is anticipated that compliance-related factors will contribute to a 10% increase in market demand. This emphasis on quality assurance is likely to shape the sputter coatings market, driving innovation and enhancing product offerings.