Expansion of Manufacturing Sector

The screw compressor market is benefiting from the expansion of the manufacturing sector in the US, which is projected to grow at a CAGR of approximately 3% over the next few years. This growth is driven by increased production activities across various industries, including automotive, aerospace, and food processing. As manufacturing processes become more complex, the need for reliable and efficient compressed air systems, such as screw compressors, becomes paramount. These compressors are favored for their ability to provide a continuous supply of compressed air, essential for powering pneumatic tools and machinery. Consequently, the robust performance of the manufacturing sector is expected to bolster the screw compressor market, as companies invest in advanced technologies to enhance productivity.

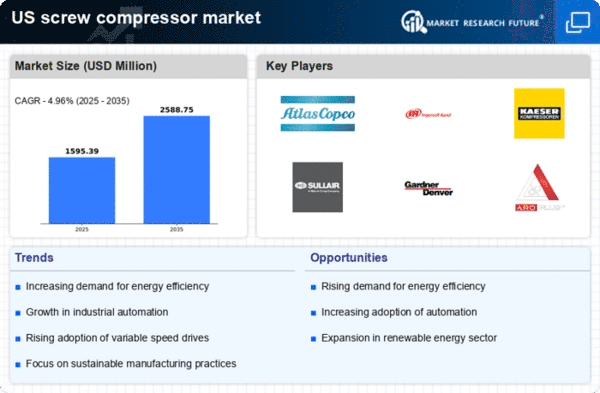

Growth in Renewable Energy Sector

The growth in the renewable energy sector is emerging as a key driver for the screw compressor market. As the US transitions towards cleaner energy sources, the demand for compressed air systems in wind and solar energy applications is increasing. Screw compressors are utilized in various processes, including the operation of pneumatic tools and equipment in renewable energy facilities. This trend is further supported by government incentives aimed at promoting renewable energy projects, which could lead to an increase in investments in infrastructure. The screw compressor market is poised to benefit from this shift, as companies seek reliable and efficient solutions to support their renewable energy initiatives.

Rising Energy Efficiency Standards

The screw compressor market is experiencing a notable shift due to the increasing energy efficiency standards mandated by regulatory bodies in the US. These standards aim to reduce energy consumption and greenhouse gas emissions, compelling manufacturers to innovate and enhance the efficiency of their products. As a result, the demand for high-efficiency screw compressors is on the rise, with many models achieving energy savings of up to 30%. This trend not only aligns with environmental goals but also offers significant cost savings for end-users, thereby driving growth in the screw compressor market. The emphasis on energy efficiency is likely to continue influencing purchasing decisions, as industries seek to comply with regulations while optimizing operational costs.

Increased Focus on Industrial Automation

The increased focus on industrial automation is reshaping the screw compressor market landscape. As industries strive to enhance productivity and reduce labor costs, the adoption of automated systems is becoming more prevalent. Screw compressors play a crucial role in these automated processes, providing the necessary compressed air for various applications, including robotics and assembly lines. The market is witnessing a surge in demand for compressors that can seamlessly integrate with automated systems, ensuring consistent performance and reliability. This trend is likely to continue, as businesses increasingly recognize the value of automation in achieving operational efficiency, thereby driving growth in the screw compressor market.

Technological Innovations in Compressor Design

Technological innovations in compressor design are significantly impacting the screw compressor market. Recent advancements, such as the integration of IoT and smart technologies, allow for real-time monitoring and predictive maintenance, enhancing operational efficiency. These innovations not only improve the reliability of screw compressors but also reduce downtime and maintenance costs. The market is witnessing a shift towards variable speed drive (VSD) technology, which can adjust the compressor's output based on demand, leading to energy savings of up to 20%. As industries increasingly adopt these advanced solutions, the screw compressor market is likely to see a surge in demand, driven by the need for enhanced performance and reduced operational costs.