US Polyimide Coatings Market Summary

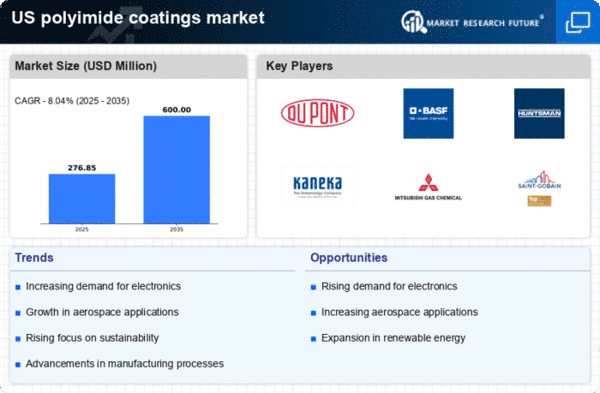

As per Market Research Future analysis, the US polyimide coatings market Size was estimated at 256.25 USD Million in 2024. The US polyimide coatings market is projected to grow from 276.85 USD Million in 2025 to 600.0 USD Million by 2035, exhibiting a compound annual growth rate (CAGR) of 8.0% during the forecast period 2025 - 2035

Key Market Trends & Highlights

The US polyimide coatings market is experiencing robust growth driven by technological advancements and increasing demand across various sectors.

- The electronics segment remains the largest, fueled by rising demand for miniaturized components.

- Sustainable solutions are gaining traction, reflecting a broader industry shift towards eco-friendly materials.

- Advancements in application techniques are enhancing the performance and efficiency of polyimide coatings.

- Technological advancements in manufacturing and the growing aerospace and defense sector are key drivers of market expansion.

Market Size & Forecast

| 2024 Market Size | 256.25 (USD Million) |

| 2035 Market Size | 600.0 (USD Million) |

| CAGR (2025 - 2035) | 8.04% |

Major Players

DuPont (US), BASF (DE), Huntsman (US), Kaneka Corporation (JP), Mitsubishi Gas Chemical Company (JP), Saint-Gobain (FR), Solvay (BE), Wacker Chemie AG (DE)