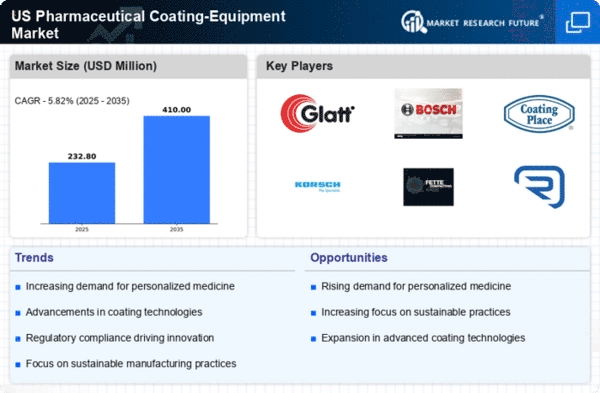

The pharmaceutical coating-equipment market is characterized by a dynamic competitive landscape, driven by innovation, regulatory compliance, and the increasing demand for advanced drug delivery systems. Key players such as Glatt (DE), Bosch Packaging Technology (DE), and Coating Place Inc (US) are strategically positioned to leverage their technological expertise and operational efficiencies. Glatt (DE) focuses on enhancing its product portfolio through continuous innovation, while Bosch Packaging Technology (DE) emphasizes partnerships to expand its market reach. Coating Place Inc (US) adopts a customer-centric approach, tailoring solutions to meet specific client needs, thereby shaping a competitive environment that prioritizes adaptability and responsiveness.The market structure appears moderately fragmented, with several players vying for market share. Key business tactics include localizing manufacturing to reduce costs and optimize supply chains, which enhances operational efficiency. The collective influence of these major companies fosters a competitive atmosphere where agility and technological advancement are paramount, allowing them to respond effectively to evolving market demands.

In October Glatt (DE) announced the launch of a new high-efficiency coating system designed to reduce production times by 30%. This strategic move is likely to enhance their competitive edge by addressing the growing need for faster production cycles in the pharmaceutical industry. Such innovations not only improve operational efficiency but also align with the industry's push towards more sustainable manufacturing practices.

In September Bosch Packaging Technology (DE) entered into a strategic partnership with a leading biopharmaceutical company to co-develop advanced coating solutions. This collaboration is indicative of Bosch's commitment to innovation and positions them to capitalize on emerging trends in biopharmaceuticals, potentially expanding their market share in this niche segment. The partnership underscores the importance of collaborative efforts in driving technological advancements within the sector.

In August Coating Place Inc (US) expanded its manufacturing capabilities by investing in state-of-the-art equipment aimed at enhancing product quality and consistency. This investment reflects a strategic focus on quality assurance, which is critical in the highly regulated pharmaceutical sector. By improving manufacturing processes, Coating Place Inc (US) is likely to strengthen its reputation and customer loyalty, further solidifying its market position.

As of November current competitive trends indicate a significant shift towards digitalization, sustainability, and the integration of AI technologies within the pharmaceutical coating-equipment market. Strategic alliances are increasingly shaping the landscape, enabling companies to pool resources and expertise to foster innovation. The competitive differentiation is expected to evolve, moving away from traditional price-based competition towards a focus on technological innovation, supply chain reliability, and sustainable practices. This transition suggests that companies that prioritize these aspects will likely emerge as leaders in the market.