Growth of the Food and Beverage Sector

The food and beverage sector is a significant driver of the packaging foams market, as the demand for safe and efficient food packaging continues to rise. With an increasing focus on food safety and quality, packaging foams are being utilized to preserve freshness and extend shelf life. In 2025, the food packaging segment is expected to account for over 30% of the total market share, highlighting its critical role in the packaging foams market. As consumers become more health-conscious, the need for reliable packaging solutions that prevent contamination and spoilage is likely to propel market growth. This trend underscores the importance of packaging foams in maintaining product integrity and consumer trust.

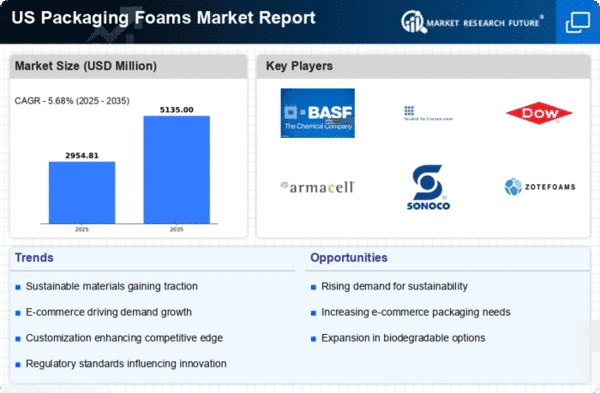

Rising Demand for Protective Packaging

The packaging foams market experiences a notable increase in demand due to the growing need for protective packaging solutions across various industries. As e-commerce continues to expand, the necessity for materials that safeguard products during transit becomes paramount. In 2025, the market is projected to reach approximately $3 billion, reflecting a compound annual growth rate (CAGR) of around 5%. This growth is driven by the need to minimize product damage and enhance customer satisfaction. Additionally, industries such as electronics and pharmaceuticals are increasingly adopting packaging foams to ensure the integrity of their products. The packaging foams market is thus positioned to benefit from this trend, as companies seek reliable and efficient packaging solutions to meet consumer expectations.

Increased Focus on Supply Chain Efficiency

The packaging foams market is experiencing a shift towards enhanced supply chain efficiency, driven by the need for cost reduction and improved logistics. Companies are increasingly seeking packaging solutions that streamline operations and reduce waste. In 2025, it is projected that businesses could save up to 20% in logistics costs by adopting optimized packaging foams. This trend is particularly relevant in the context of just-in-time inventory systems, where efficient packaging plays a crucial role in minimizing delays and ensuring timely deliveries. The packaging foams market is thus likely to benefit from this focus on efficiency, as companies strive to enhance their operational capabilities while meeting customer demands.

Regulatory Compliance and Safety Standards

The packaging foams market is significantly influenced by stringent regulatory compliance and safety standards imposed by government agencies. These regulations ensure that packaging materials meet safety and environmental criteria, which is crucial for industries such as pharmaceuticals and food. In 2025, it is anticipated that compliance costs could rise by 15%, prompting companies to invest in high-quality packaging foams that adhere to these standards. The packaging foams market must navigate these challenges while maintaining cost-effectiveness. As a result, manufacturers are likely to prioritize the development of compliant materials that not only meet regulatory requirements but also appeal to environmentally conscious consumers.

Technological Advancements in Foam Production

Technological innovations in the production of packaging foams are significantly influencing the market landscape. Advanced manufacturing techniques, such as the use of biodegradable materials and improved foam formulations, are enhancing the performance and sustainability of packaging solutions. In 2025, it is estimated that the adoption of these technologies could lead to a 10% reduction in production costs, thereby making packaging foams more accessible to a wider range of businesses. The packaging foams market is likely to see increased competition as companies invest in research and development to create superior products. This focus on innovation not only meets regulatory requirements but also aligns with consumer preferences for environmentally friendly options.