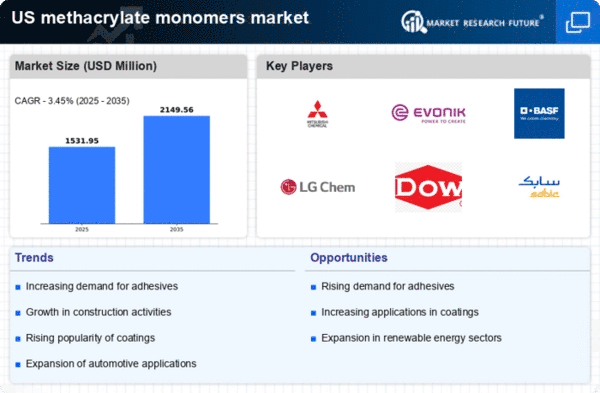

Growth in the Coatings Industry

The coatings industry is a significant driver of the methacrylate monomers market, as these monomers are essential in formulating high-performance coatings. The increasing demand for protective and decorative coatings across various sectors, including automotive, industrial, and architectural, is expected to boost the consumption of methacrylate monomers. In 2025, the coatings segment is projected to account for approximately 35% of the total market share. This growth is likely influenced by the rising awareness of aesthetic appeal and the need for durable finishes that can withstand harsh environmental conditions. Furthermore, advancements in coating technologies that utilize methacrylate monomers are anticipated to enhance product performance, thereby driving further demand in the methacrylate monomers market.

Rising Demand in Automotive Sector

The automotive industry is experiencing a notable surge in demand for methacrylate monomers, primarily due to their application in manufacturing lightweight and durable components. As vehicle manufacturers increasingly focus on enhancing fuel efficiency and reducing emissions, the use of methacrylate-based materials in automotive applications appears to be a strategic choice. In 2025, the automotive sector is projected to account for approximately 30% of the total consumption of methacrylate monomers in the US. This trend is likely driven by the growing adoption of electric vehicles, which require advanced materials for battery casings and structural components. Consequently, the methacrylate monomers market is expected to benefit significantly from this rising demand, as manufacturers seek to innovate and improve the performance of automotive products.

Expansion of Construction Activities

The construction industry in the US is witnessing robust growth, which is likely to propel the methacrylate monomers market. With an increasing number of infrastructure projects and residential developments, the demand for high-performance adhesives and sealants is on the rise. Methacrylate monomers are favored for their excellent bonding properties and resistance to environmental factors, making them ideal for construction applications. In 2025, the construction sector is anticipated to represent around 25% of the methacrylate monomers market. This expansion is further supported by government initiatives aimed at improving infrastructure, which could lead to increased investments in construction materials. As a result, the methacrylate monomers market is positioned to experience substantial growth driven by these construction activities.

Innovations in Adhesive Technologies

Innovations in adhesive technologies are playing a crucial role in shaping the methacrylate monomers market. The development of new formulations that incorporate methacrylate monomers is enabling manufacturers to produce adhesives with superior bonding strength and durability. This is particularly relevant in industries such as aerospace and electronics, where high-performance adhesives are essential. In 2025, the adhesive segment is expected to represent around 20% of the methacrylate monomers market. The ongoing research and development efforts aimed at enhancing adhesive properties are likely to create new opportunities for growth. As industries continue to seek advanced bonding solutions, the methacrylate monomers market stands to benefit from these technological advancements.

Increasing Focus on Renewable Resources

The methacrylate monomers market is also influenced by the increasing focus on renewable resources and sustainable practices. Manufacturers are exploring bio-based alternatives to traditional methacrylate monomers, which could potentially reduce the environmental impact associated with their production. This shift towards sustainability is becoming more pronounced as consumers and regulatory bodies demand greener products. In 2025, it is estimated that bio-based methacrylate monomers could capture up to 15% of the market share. This trend suggests that the methacrylate monomers market may evolve to incorporate more sustainable practices, aligning with broader environmental goals and consumer preferences.