Rising Demand for Operational Efficiency

The US Machine Condition Monitoring Market is experiencing a notable surge in demand for operational efficiency across various sectors. Companies are increasingly adopting condition monitoring solutions to enhance productivity and reduce downtime. According to recent data, organizations that implement these technologies can achieve up to a 30% reduction in maintenance costs. This trend is particularly evident in manufacturing and energy sectors, where the need for uninterrupted operations is paramount. As businesses strive to optimize their processes, the integration of advanced monitoring systems becomes essential. The focus on operational efficiency not only drives the adoption of condition monitoring solutions but also fosters a competitive edge in the market. Consequently, this driver is likely to propel the growth of the US Machine Condition Monitoring Market in the coming years.

Regulatory Compliance and Industry Standards

Regulatory compliance and adherence to industry standards are pivotal drivers in the US Machine Condition Monitoring Market. As regulations surrounding equipment safety and environmental impact become more stringent, organizations are compelled to adopt condition monitoring solutions to ensure compliance. The market data indicates that companies that implement monitoring systems can achieve a 15% reduction in compliance-related costs. This is particularly relevant in sectors such as manufacturing and transportation, where regulatory oversight is rigorous. By investing in condition monitoring technologies, organizations not only meet compliance requirements but also enhance their operational efficiency. This dual benefit is likely to drive the growth of the US Machine Condition Monitoring Market in the foreseeable future.

Increased Focus on Safety and Risk Management

The US Machine Condition Monitoring Market is witnessing an increased focus on safety and risk management. Organizations are prioritizing the implementation of condition monitoring systems to mitigate risks associated with equipment failures. This is particularly relevant in industries such as oil and gas, where equipment malfunctions can lead to catastrophic incidents. By utilizing monitoring technologies, companies can enhance their safety protocols and ensure compliance with regulatory standards. The market data indicates that organizations investing in condition monitoring solutions can reduce workplace accidents by up to 25%. This heightened emphasis on safety not only protects employees but also safeguards company assets, thereby driving the growth of the US Machine Condition Monitoring Market.

Technological Advancements in Monitoring Solutions

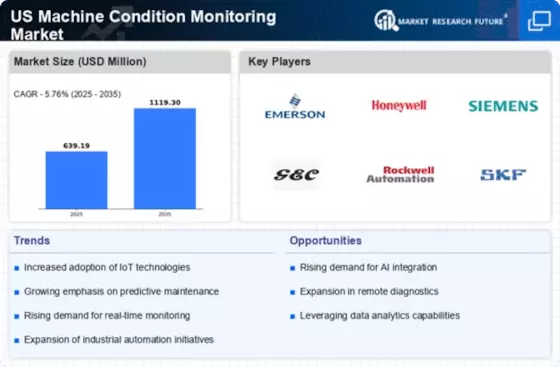

Technological advancements are significantly shaping the US Machine Condition Monitoring Market. Innovations such as artificial intelligence, machine learning, and advanced sensor technologies are enhancing the capabilities of monitoring systems. These advancements enable real-time data analysis and predictive maintenance, allowing organizations to identify potential failures before they occur. For instance, the integration of AI algorithms can lead to a 20% increase in predictive accuracy, thereby minimizing unexpected equipment failures. As industries increasingly recognize the value of these technologies, the demand for sophisticated monitoring solutions is expected to rise. This trend not only improves operational reliability but also contributes to the overall growth of the US Machine Condition Monitoring Market.

Growing Adoption of Predictive Maintenance Strategies

The growing adoption of predictive maintenance strategies is a key driver in the US Machine Condition Monitoring Market. Companies are increasingly shifting from traditional maintenance approaches to predictive models that leverage real-time data. This transition is driven by the need to minimize downtime and extend equipment lifespan. Market analysis suggests that predictive maintenance can lead to a 10-15% increase in equipment availability. As organizations recognize the financial benefits of predictive maintenance, the demand for condition monitoring solutions is expected to rise. This trend not only enhances operational efficiency but also contributes to the sustainability goals of businesses, further propelling the growth of the US Machine Condition Monitoring Market.