Integration of Industry 4.0 Technologies

The integration of Industry 4.0 technologies is transforming the cnc machine market, as manufacturers increasingly adopt smart manufacturing practices. This includes the use of IoT, big data analytics, and artificial intelligence to optimize production processes. By leveraging these technologies, companies can enhance operational efficiency, reduce downtime, and improve product quality. The cnc machine market is likely to see a significant increase in demand for machines equipped with advanced connectivity features, enabling real-time monitoring and data-driven decision-making. As a result, the market is expected to witness a growth rate of around 8% annually, driven by the need for smarter, more efficient manufacturing solutions.

Rising Demand for Precision Manufacturing

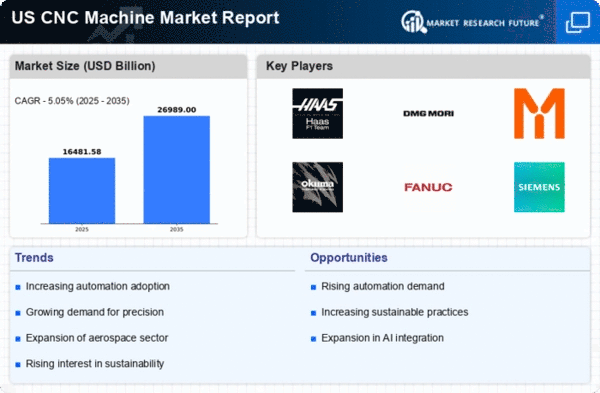

The cnc machine market is experiencing a notable surge in demand for precision manufacturing across various sectors, including aerospace, automotive, and medical devices. This trend is driven by the increasing need for high-quality components that meet stringent tolerances and specifications. As industries strive for enhanced efficiency and reduced waste, the adoption of CNC machines, which offer superior accuracy and repeatability, becomes essential. In 2025, the market is projected to grow at a CAGR of approximately 7.5%, reflecting the industry's shift towards automation and precision engineering. The cnc machine market is thus positioned to benefit from this growing emphasis on quality and precision in manufacturing processes.

Growth in the Aerospace and Defense Sector

The aerospace and defense sector is a critical driver for the cnc machine market, as it requires highly specialized components that demand advanced machining capabilities. With the ongoing expansion of this sector, fueled by increased defense budgets and the rise of commercial aerospace projects, the demand for CNC machines is expected to rise significantly. In 2025, the aerospace and defense industries are projected to account for approximately 25% of the total market share in the cnc machine market. This growth is indicative of the sector's reliance on precision machining to produce complex parts that meet rigorous safety and performance standards.

Increased Investment in Automation and Robotics

The cnc machine market is benefiting from increased investment in automation and robotics, as manufacturers seek to enhance productivity and reduce labor costs. The integration of robotic systems with CNC machines allows for greater efficiency and precision in manufacturing processes. This trend is particularly relevant in sectors where labor shortages are prevalent, prompting companies to automate their operations. The cnc machine market is projected to grow by approximately 7% annually, as businesses recognize the potential of automation to streamline production and improve overall competitiveness.

Shift Towards Customization and Shorter Production Runs

The cnc machine market is witnessing a shift towards customization and shorter production runs, driven by changing consumer preferences and market dynamics. As businesses seek to differentiate their products, the demand for CNC machines capable of producing small batches with high customization levels is increasing. This trend is particularly evident in industries such as consumer electronics and automotive, where rapid prototyping and tailored solutions are essential. The cnc machine market is likely to see a growth rate of around 6% as manufacturers invest in flexible machining solutions that can adapt to varying production requirements.