Expansion of End-Use Industries

The aromatic ketone-polymer market is significantly influenced by the expansion of end-use industries, particularly in the automotive and construction sectors. As these industries grow, the demand for innovative materials that offer superior performance characteristics is expected to increase. For instance, the automotive sector is focusing on lightweight materials to improve fuel efficiency, while the construction industry seeks durable and weather-resistant materials. This expansion is anticipated to contribute to a market growth rate of approximately 5.8% annually through 2025. Consequently, the aromatic ketone-polymer market is poised to benefit from these developments, as manufacturers align their offerings with the evolving needs of these industries.

Growing Focus on Lightweight Solutions

The growing focus on lightweight solutions across various industries is significantly impacting the aromatic ketone-polymer market. As companies strive to improve energy efficiency and reduce emissions, the demand for lightweight materials is becoming increasingly critical. This trend is particularly evident in the automotive and aerospace sectors, where reducing weight can lead to substantial fuel savings. The aromatic ketone-polymer market is well-positioned to capitalize on this trend, as these polymers offer excellent strength-to-weight ratios. Market analysts predict that the emphasis on lightweight solutions could drive a growth rate of around 5.5% through 2025, further solidifying the aromatic ketone-polymer market's relevance in modern manufacturing.

Regulatory Support for Advanced Materials

Regulatory frameworks in the US are increasingly supportive of advanced materials, which is likely to bolster the aromatic ketone-polymer market. Government initiatives aimed at promoting innovation and sustainability in manufacturing processes are encouraging the adoption of high-performance polymers. For example, regulations that mandate the use of environmentally friendly materials in construction and automotive applications are driving manufacturers to explore aromatic ketone polymers. This regulatory support is expected to enhance market growth, with projections indicating a potential increase in market size by 7% by 2026. Such policies not only foster innovation but also create a conducive environment for the aromatic ketone-polymer market to thrive.

Rising Demand for High-Performance Materials

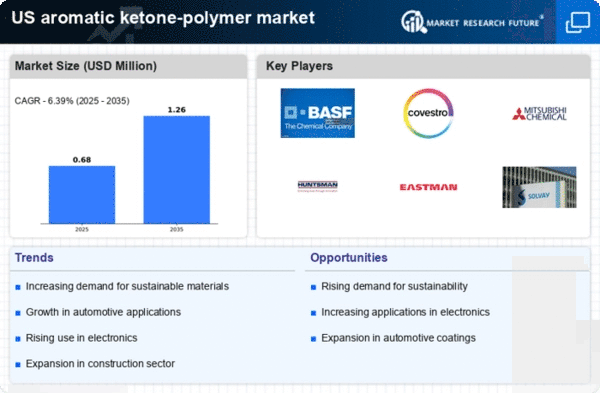

The aromatic ketone-polymer market is experiencing a notable increase in demand for high-performance materials across various industries. This trend is driven by the need for lightweight, durable, and chemically resistant materials in sectors such as automotive, aerospace, and electronics. As manufacturers seek to enhance product performance and reduce weight, the adoption of aromatic ketone polymers is likely to rise. In 2025, the market is projected to reach approximately $1.5 billion, reflecting a compound annual growth rate (CAGR) of around 6.5%. This growth indicates a shift towards advanced materials that can withstand extreme conditions, thereby propelling the aromatic ketone-polymer market forward.

Technological Innovations in Polymer Production

Technological innovations in polymer production are playing a crucial role in shaping the aromatic ketone-polymer market. Advances in manufacturing techniques, such as improved polymerization processes and the development of new catalysts, are enhancing the efficiency and quality of aromatic ketone polymers. These innovations enable manufacturers to produce polymers with tailored properties, meeting specific industry requirements. As a result, the market is likely to witness a surge in product offerings, catering to diverse applications. The impact of these technological advancements is projected to contribute to a market growth rate of approximately 6% annually, indicating a robust future for the aromatic ketone-polymer market.