Sustainability Initiatives

The aircraft fuel-tanks market is increasingly influenced by sustainability initiatives aimed at reducing the environmental impact of aviation. Regulatory bodies in the US are advocating for greener technologies, which include the development of lightweight and fuel-efficient fuel-tanks. The adoption of advanced materials, such as composite structures, is gaining traction, potentially reducing fuel consumption by up to 15%. This shift not only aligns with environmental goals but also enhances the performance of aircraft. As airlines and manufacturers prioritize sustainability, the aircraft fuel-tanks market is likely to see innovations that cater to these demands. The integration of eco-friendly practices into production processes may also lead to cost savings, further incentivizing stakeholders to invest in sustainable solutions.

Rising Military Expenditure

The aircraft fuel-tanks market is significantly impacted by the rising military expenditure in the US. With defense budgets increasing, there is a heightened focus on modernizing military aircraft fleets. The Department of Defense has allocated substantial funds for the procurement of advanced aircraft, which necessitates the development of specialized fuel-tanks. This trend is particularly evident in the procurement of fighter jets and unmanned aerial vehicles (UAVs), where performance and reliability are paramount. As military contracts expand, the aircraft fuel-tanks market is likely to benefit from increased demand for high-performance fuel-tanks tailored to meet stringent military specifications. This growth trajectory suggests a robust future for manufacturers catering to the defense sector.

Increased Aircraft Production

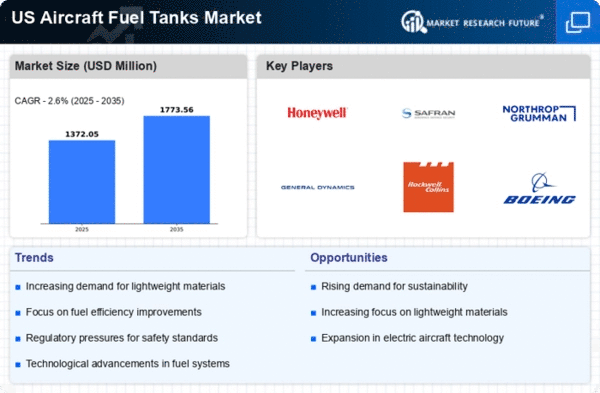

The aircraft fuel-tanks market is experiencing a notable surge due to the rising production of commercial and military aircraft. In the US, the Federal Aviation Administration (FAA) reported a steady increase in aircraft deliveries, with a projected growth rate of approximately 4% annually. This uptick in production necessitates a corresponding demand for fuel-tanks, as they are integral to aircraft functionality. The expansion of the aerospace sector, driven by both passenger travel and defense spending, further amplifies this demand. As manufacturers ramp up production to meet market needs, the aircraft fuel-tanks market is poised for significant growth, reflecting the broader trends in the aviation industry. This dynamic environment suggests that stakeholders in the aircraft fuel-tanks market must remain agile to capitalize on emerging opportunities.

Expansion of Regional Airlines

The aircraft fuel-tanks market is witnessing growth driven by the expansion of regional airlines across the US. As these airlines increase their fleet sizes to accommodate rising passenger numbers, the demand for fuel-tanks is expected to rise correspondingly. The Regional Airline Association has reported a resurgence in regional travel, with an anticipated growth rate of 5% annually. This trend is likely to stimulate investments in new aircraft, which in turn will require advanced fuel-tank solutions. The focus on enhancing operational efficiency and reducing costs among regional carriers further emphasizes the need for innovative fuel-tank designs. Consequently, the aircraft fuel-tanks market stands to gain from this expansion, as manufacturers align their offerings with the evolving needs of regional airlines.

Technological Innovations in Fuel Management

Technological advancements in fuel management systems are reshaping the aircraft fuel-tanks market. Innovations such as smart fuel-tank monitoring systems enable real-time data collection and analysis, enhancing operational efficiency. These systems can potentially reduce fuel wastage by up to 20%, translating into substantial cost savings for airlines. Furthermore, the integration of Internet of Things (IoT) technology allows for predictive maintenance, minimizing downtime and improving safety. As the aviation industry increasingly embraces digital transformation, the demand for advanced fuel management solutions is expected to rise. This trend indicates a shift towards more sophisticated fuel-tank designs that incorporate these technologies, thereby driving growth in the aircraft fuel-tanks market.