Rising Demand for Natural Gas

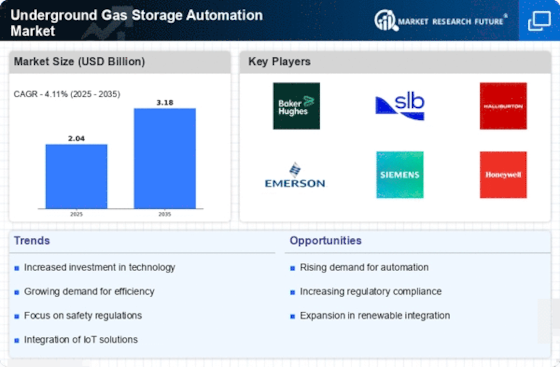

The rising demand for natural gas as a cleaner energy source is a significant driver for the Underground Gas Storage Automation Market. As countries transition towards more sustainable energy solutions, the need for efficient gas storage becomes paramount. The International Energy Agency has projected that natural gas consumption will increase by approximately 30% by 2040, necessitating enhanced storage capabilities. Automation technologies play a crucial role in managing this demand, allowing for more efficient gas storage and retrieval processes. This trend is likely to stimulate investments in automation technologies, further driving market growth.

Technological Advancements in Automation

Technological advancements in automation are reshaping the Underground Gas Storage Automation Market. Innovations such as artificial intelligence, machine learning, and advanced robotics are being integrated into gas storage operations, enhancing efficiency and reducing operational costs. These technologies enable predictive maintenance, which minimizes equipment failures and extends the lifespan of storage facilities. The market is expected to benefit from these advancements, as companies increasingly adopt automated solutions to streamline their operations. The potential for cost savings and improved performance is likely to attract further investment in automation technologies.

Integration of Advanced Monitoring Systems

The integration of advanced monitoring systems is a pivotal driver for the Underground Gas Storage Automation Market. These systems utilize real-time data analytics and IoT technologies to enhance operational efficiency and safety. By enabling continuous monitoring of gas storage conditions, operators can promptly identify anomalies and mitigate risks. The market for monitoring systems is projected to grow significantly, with estimates suggesting a compound annual growth rate of over 10% in the coming years. This trend indicates a strong demand for automated solutions that can provide accurate data and predictive insights, thereby optimizing gas storage operations and reducing downtime.

Regulatory Compliance and Safety Standards

Regulatory compliance and safety standards are increasingly influencing the Underground Gas Storage Automation Market. Governments and regulatory bodies are imposing stringent safety regulations to ensure the integrity of gas storage facilities. Compliance with these regulations often necessitates the adoption of automated systems that can monitor and report on safety metrics in real-time. The market is witnessing a surge in demand for automation solutions that facilitate adherence to these regulations, as non-compliance can lead to severe penalties and operational disruptions. This driver is expected to propel the market forward, as companies seek to enhance their safety protocols through automation.

Increased Investment in Energy Infrastructure

Increased investment in energy infrastructure is a critical driver for the Underground Gas Storage Automation Market. Governments and private entities are allocating substantial resources to upgrade and expand energy infrastructure, including gas storage facilities. This investment is often accompanied by a push for automation to enhance operational efficiency and safety. According to recent reports, investments in energy infrastructure are expected to reach trillions of dollars over the next decade. This influx of capital is likely to accelerate the adoption of automated solutions in gas storage, as stakeholders seek to modernize their operations and meet growing energy demands.