Growth in Oil and Gas Sector

The oil and gas sector in the UK is witnessing a resurgence, which may positively influence the reciprocating compressor market. With the increasing exploration and production activities in the North Sea, there is a heightened demand for reliable compression solutions. Reciprocating compressors are essential for various applications in this sector, including gas processing and transportation. The UK government has projected that the oil and gas sector could contribute approximately £50 billion to the economy by 2025, indicating a robust market for reciprocating compressors. Additionally, the need for enhanced safety and efficiency in operations is likely to drive the adoption of advanced compressor technologies. As the oil and gas sector continues to evolve, the reciprocating compressor market is expected to benefit from this growth.

Increased Focus on Energy Efficiency

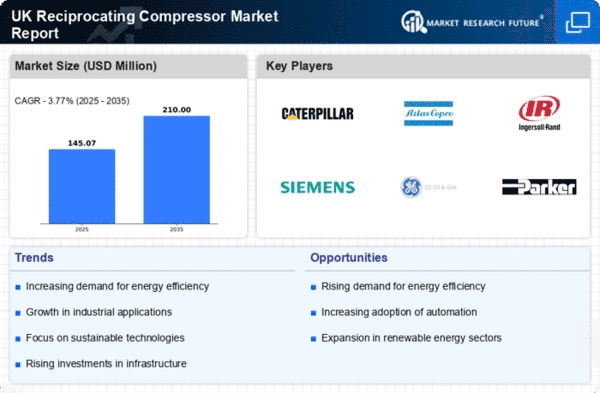

The growing emphasis on energy efficiency in the UK is influencing the reciprocating compressor market. With rising energy costs and stringent regulations aimed at reducing carbon emissions, industries are increasingly seeking energy-efficient solutions. Reciprocating compressors, known for their efficiency and reliability, are becoming a preferred choice for various applications. The UK government has set ambitious targets to reduce greenhouse gas emissions by 68% by 2030, which may drive industries to adopt more efficient technologies. In 2025, it is estimated that energy-efficient compressors could reduce operational costs by up to 30%, making them an attractive investment for businesses. This focus on energy efficiency is likely to propel the demand for reciprocating compressors, as companies strive to meet regulatory requirements and enhance their sustainability profiles.

Rising Demand in Manufacturing Sector

The manufacturing sector in the UK is experiencing a notable resurgence, which appears to be driving the growth of the reciprocating compressor market. As industries such as automotive, aerospace, and food processing expand, the need for efficient and reliable compression solutions becomes increasingly critical. In 2025, the manufacturing sector is projected to contribute approximately £200 billion to the UK economy, indicating a robust demand for reciprocating compressors. These compressors are essential for various applications, including refrigeration and air conditioning, which are integral to manufacturing processes. The increasing focus on production efficiency and cost reduction further propels the adoption of reciprocating compressors, as they offer high reliability and performance. Consequently, the growth of the manufacturing sector is likely to be a significant driver for the reciprocating compressor market in the UK.

Infrastructure Development Initiatives

Infrastructure development initiatives in the UK are poised to create substantial opportunities for the reciprocating compressor market. The government has committed to investing over £600 billion in infrastructure projects over the next decade, focusing on transportation, energy, and utilities. These projects necessitate the use of reciprocating compressors for various applications, including powering pneumatic tools and providing compressed air for construction activities. The demand for energy-efficient and high-performance compressors is likely to increase as infrastructure projects progress. Furthermore, the emphasis on sustainable construction practices may lead to the adoption of advanced reciprocating compressor technologies that align with environmental standards. As a result, the ongoing infrastructure development initiatives are expected to significantly impact the growth trajectory of the reciprocating compressor market.

Technological Innovations in Compressor Design

Technological innovations in compressor design are emerging as a key driver for the reciprocating compressor market. The development of advanced materials and smart technologies is enhancing the performance and efficiency of these compressors. Innovations such as variable speed drives and advanced control systems are enabling better energy management and operational efficiency. In 2025, it is anticipated that the market for technologically advanced compressors will grow by approximately 15%, reflecting the increasing demand for high-performance solutions. Furthermore, the integration of IoT technologies into compressor systems is likely to provide real-time monitoring and predictive maintenance capabilities, which can significantly reduce downtime and operational costs. As industries in the UK seek to optimize their operations, the focus on technological innovations is expected to propel the growth of the reciprocating compressor market.