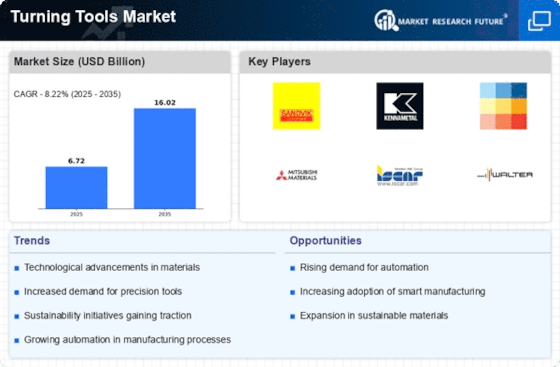

Top Industry Leaders in the Turning Tools Market

The global turning tools market is a dynamic space. Turning tools are essential for shaping cylindrical parts on lathes, used in various industries like automotive, aerospace, and general machining. This market is driven by factors like rising automation, demand for high-precision components, and increasing industrial activity in emerging economies.

Strategies Adopted:

- Product Differentiation: Leading players invest heavily in R&D to develop high-performance materials, innovative geometries, and specialized tool coatings. This caters to diverse customer needs and helps in premium product positioning.

- Digitalization and Automation: Integrating digital technologies like tool management systems and predictive maintenance solutions allows for optimized tool usage, reduced downtime, and increased efficiency.

- Partnerships and Acquisitions: Collaborations with technology providers, distributors, and other industry players are becoming increasingly common to expand reach, access new markets, and share expertise.

- Focus on Sustainability: Environmental concerns are driving the development of eco-friendly turning tools, using recycled materials and reducing waste generation.

Factors for Market Share:

- Product Quality and Performance: Reliable tools that deliver consistent results and high productivity are crucial for customer satisfaction and market retention.

- Pricing and Value Proposition: Balancing competitive pricing with innovative features and superior performance is key to attracting and retaining customers.

- Brand Reputation and Customer Service: Strong brand recognition and prompt, reliable customer service build trust and loyalty, leading to repeat business.

- Distribution Network and Reach: Efficient distribution channels and strong partnerships with distributors ensure timely delivery and access to a wider customer base.

- Adaptability and Innovation: The ability to adapt to changing market trends and technological advancements is crucial for staying ahead of the competition.

List of Key Players in the Turning Tools Market

- Ingersoll Cutting Tool Company (U.S.)

- Sandvik Group (Sweden)

- Mikron Tool SA Agno (Switzerland)

- NTK Cutting Tools (Japan)

- WNT Tools India Pvt Ltd. (India)

- Kennametal Foundation (U.S.)

- Hanjiang Tool Co., Ltd. (China)

- Shanghai Tool Works Co.,Ltd. (China)

- Union Tool Corporation (Japan)

- ISCAR LTD. (Israel)

Recent Developments:

August 2023: Kennametal acquires Tungaloy, a South Korean cutting tool manufacturer, expanding its presence in the Asian market.

September 2023: Iscar introduces a new line of CBN inserts for high-speed machining of hard materials like ceramics and composites.

October 2023: Seco Tools partners with Siemens MindSphere to develop AI-powered tool monitoring and optimization solutions.

November 2023: YG-1 invests in a new manufacturing facility in Vietnam to cater to the growing demand in Southeast Asia.

December 2023: The International Metalworking Show (IMTS) showcases the latest turning tool technologies and trends, with a focus on automation and digitalization.