Increased Focus on Miniaturization

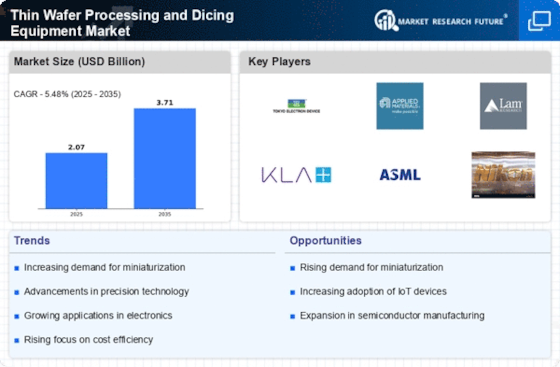

The trend towards miniaturization in electronics is a significant driver for the Thin Wafer Processing and Dicing Equipment Market. As consumer electronics become more compact, the demand for thinner wafers has escalated. This miniaturization trend is not only limited to smartphones but extends to wearables, medical devices, and automotive applications. The market for thin wafers is expected to grow at a compound annual growth rate of approximately 10% over the next few years, reflecting the industry's shift towards smaller form factors. Manufacturers are thus compelled to adopt advanced dicing technologies that can efficiently process thinner wafers without compromising quality. This focus on miniaturization is likely to continue influencing the design and production of electronic components, further driving the Thin Wafer Processing and Dicing Equipment Market.

Technological Advancements in Dicing Techniques

Technological advancements in dicing techniques are playing a crucial role in shaping the Thin Wafer Processing and Dicing Equipment Market. Innovations such as laser dicing and water jet dicing are gaining traction due to their ability to enhance precision and reduce material waste. These advanced techniques allow for the processing of thinner wafers with minimal damage, which is essential for maintaining the integrity of semiconductor devices. The market for laser dicing equipment alone is projected to grow significantly, driven by the increasing need for high-precision dicing solutions. As manufacturers seek to improve yield rates and reduce production costs, the adoption of these advanced dicing technologies is expected to rise, thereby propelling the Thin Wafer Processing and Dicing Equipment Market forward.

Expansion of the Electronics Manufacturing Sector

The expansion of the electronics manufacturing sector is a pivotal driver for the Thin Wafer Processing and Dicing Equipment Market. As countries invest in their manufacturing capabilities, the demand for high-quality electronic components continues to rise. The electronics manufacturing services market is projected to reach over 1 trillion dollars by 2025, highlighting the sector's robust growth. This expansion is accompanied by an increasing need for advanced thin wafer processing and dicing equipment to meet the production demands of various electronic devices. Manufacturers are thus compelled to upgrade their equipment to ensure efficiency and precision in production. This ongoing expansion in electronics manufacturing is likely to sustain the growth momentum of the Thin Wafer Processing and Dicing Equipment Market.

Growing Investment in Renewable Energy Technologies

The shift towards renewable energy technologies is emerging as a key driver for the Thin Wafer Processing and Dicing Equipment Market. As the demand for solar cells and other renewable energy solutions increases, the need for efficient thin wafer processing becomes critical. The solar photovoltaic market is anticipated to grow substantially, with projections indicating a market size exceeding 200 billion dollars by 2025. This growth necessitates the use of advanced dicing equipment to produce high-quality solar cells from thin wafers. Manufacturers are increasingly investing in technologies that enhance the efficiency and effectiveness of wafer processing, aligning with sustainability goals. This trend not only supports the growth of the Thin Wafer Processing and Dicing Equipment Market but also contributes to broader environmental initiatives.

Rising Demand for Advanced Semiconductor Technologies

The Thin Wafer Processing and Dicing Equipment Market is experiencing a surge in demand driven by the increasing complexity of semiconductor devices. As technology advances, the need for smaller, more efficient chips has become paramount. This trend is evident in the growing adoption of 5G technology and the Internet of Things (IoT), which require high-performance semiconductors. According to recent data, the semiconductor market is projected to reach a value of over 500 billion dollars by 2025, indicating a robust growth trajectory. This demand for advanced semiconductor technologies necessitates sophisticated thin wafer processing and dicing equipment, which can handle the precision required for modern applications. Consequently, manufacturers are investing in innovative equipment to meet these evolving needs, thereby propelling the growth of the Thin Wafer Processing and Dicing Equipment Market.