Regulatory Compliance

Regulatory frameworks aimed at enhancing product safety and environmental protection are influencing the Thermoplastic Elastomers (TPE) Market. Stricter regulations regarding material safety and environmental impact are prompting manufacturers to adopt TPEs, which often meet or exceed these standards. For example, TPEs are frequently used in food contact applications due to their compliance with safety regulations, making them a preferred choice for packaging and kitchenware. The market is likely to benefit from the increasing enforcement of regulations that favor the use of safer, more sustainable materials. This compliance not only mitigates risks for manufacturers but also enhances consumer trust, thereby driving demand for TPEs across various industries.

Technological Innovations

Technological advancements in polymer science are significantly influencing the Thermoplastic Elastomers (TPE) Market. Innovations in processing techniques and material formulations are enabling the development of TPEs with enhanced properties, such as improved thermal stability and mechanical performance. For instance, the introduction of new additives and compounding methods has led to TPEs that can withstand extreme conditions, making them suitable for a broader range of applications. The market is expected to witness a surge in demand for specialized TPEs, particularly in sectors like healthcare and electronics, where performance and reliability are paramount. This trend suggests that ongoing research and development efforts will continue to shape the landscape of the TPE market.

Sustainability Initiatives

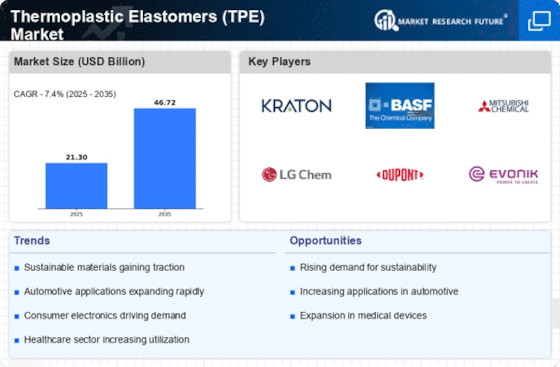

The increasing emphasis on sustainability appears to be a pivotal driver for the Thermoplastic Elastomers (TPE) Market. As industries strive to reduce their environmental footprint, TPEs, known for their recyclability and lower emissions during production, are gaining traction. The market for TPEs is projected to grow at a compound annual growth rate of approximately 5.5% from 2023 to 2028, driven by the demand for eco-friendly materials. Companies are increasingly adopting TPEs in applications such as automotive parts and consumer goods, where sustainability is becoming a key purchasing criterion. This shift not only aligns with regulatory pressures but also caters to the growing consumer preference for sustainable products, thereby enhancing the market's appeal.

Diverse Application Spectrum

The versatility of Thermoplastic Elastomers Market (TPE) is a crucial driver for the TPE Market. TPEs are utilized across various sectors, including automotive, consumer goods, medical devices, and construction, due to their unique properties such as flexibility, durability, and ease of processing. The automotive sector, in particular, is experiencing a notable shift towards TPEs for applications like seals, gaskets, and interior components, driven by the need for lightweight materials that enhance fuel efficiency. Furthermore, the medical industry is increasingly adopting TPEs for their biocompatibility and sterilization capabilities. This broad application spectrum indicates a robust growth potential for the TPE market, as manufacturers seek to leverage the advantages of TPEs in diverse product offerings.

Economic Growth and Urbanization

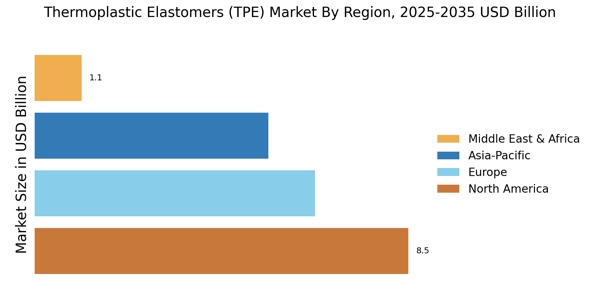

Economic growth and urbanization trends are contributing to the expansion of the Thermoplastic Elastomers (TPE) Market. As economies develop, there is a rising demand for consumer products, automotive components, and construction materials, all of which increasingly incorporate TPEs. Urbanization leads to higher standards of living and increased consumption of goods, further propelling the demand for TPEs in various applications. The construction sector, for instance, is utilizing TPEs for roofing membranes and sealants, driven by the need for durable and weather-resistant materials. This correlation between economic development and TPE demand suggests a promising outlook for the market, as urbanization continues to shape consumer preferences and industrial requirements.