Market Trends

Key Emerging Trends in the Superabsorbent Polymers Market

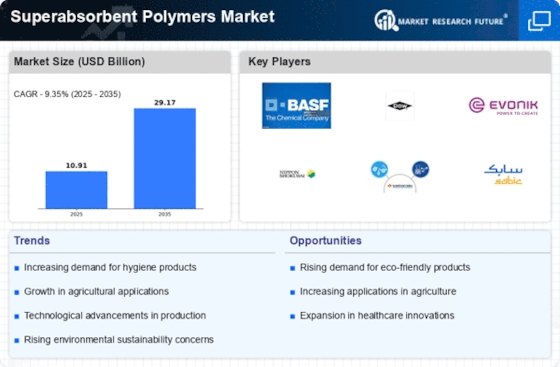

The Superabsorbent Polymers (SAP) market has seen outstanding patterns as of late, mirroring a unique scene driven by different elements. Developing Interest in Cleanliness Items: The rising demand for superabsorbent polymers in feminine hygiene products like diapers is one of the most important market trends. The capacity of SAP to assimilate and hold a lot of fluid makes it a urgent part in improving the presentation of these items. Rising Natural Worries: Natural contemplations are forming the market elements, with a developing accentuation on maintainable and eco-accommodating other options. Makers are investigating bio-based superabsorbent polymers to address natural worries and decrease the environmental impression related with conventional oil based polymers. Growing Horticultural Applications: Agriculture uses superabsorbent polymers, particularly in products that absorb water for soil conditioning. As water shortage turns into a worldwide concern, the utilization of SAP in horticulture is building up forward momentum, as it further develops water maintenance in soil, in this way improving harvest yield and lessening the general water necessity. Mechanical Progressions: Continuous innovative work endeavors are driving mechanical headways in superabsorbent polymers. Advancements in polymer science and assembling processes are pointed toward further developing the exhibition attributes of SAP, like assimilation limit, soundness, and biodegradability. Shift Towards Biodegradable Other options: The market is seeing a shift towards biodegradable superabsorbent polymers as a reaction to the rising consciousness of ecological issues. Biodegradable SAPs offer a supportable arrangement by breaking down into regular parts, limiting long haul ecological effect. Local Market Elements: The market trends vary geographically, with distinct dynamics in each region. For example, Asia-Pacific is a critical customer of superabsorbent polymers, driven by a blossoming populace, expanding extra cash, and a rising interest for cleanliness items. In the mean time, North America and Europe are seeing a flood popular for eco-accommodating other options, mirroring the developing natural cognizance in these locales. Joint efforts and Organizations: Industry players are progressively captivating in coordinated efforts and organizations to use correlative qualities and encourage advancement. Cooperative endeavors plan to speed up the advancement of better than ever superabsorbent polymer items, taking special care of assorted applications and market requests. Administrative Scene: The administrative climate assumes an essential part in molding market patterns. Rigid guidelines connected with item wellbeing, natural effect, and naming are affecting the assembling and advertising methodologies of superabsorbent polymer makers. Consistence with principles and confirmations is turning into a critical differentiator in the cutthroat scene. Changes in the expense of natural substances: The market for superabsorbent polymers is affected by fluctuations in the prices of raw materials, particularly those derived from petrochemical sources. Variances in natural substance costs influence the general creation cost, accordingly, impacting item evaluating methodologies and market seriousness. Covid Impact: The market for superabsorbent polymers is harmed by the coronavirus pandemic. While there was a hidden aggravation in the store network due to lockdowns and limits, the extended focus on neatness and clinical benefits things has provoked a flood well known for superabsorbent polymers in the improvement of individual protective equipment and clinical things.

Leave a Comment