Growth in Consumer Goods Sector

The Styrene Ethylene Butylene Styrene Market is benefiting from growth in the consumer goods sector. SEBS is increasingly utilized in the production of various consumer products, including household items, toys, and personal care products, due to its desirable properties such as flexibility and durability. As consumer preferences shift towards high-quality and versatile materials, the demand for SEBS is likely to rise. Market data suggests that the consumer goods sector could drive a growth rate of around 5% for SEBS through 2025. This trend indicates a promising outlook for SEBS as manufacturers seek to enhance product performance and meet consumer expectations.

Innovations in Polymer Technology

Innovations in polymer technology are playing a pivotal role in shaping the Styrene Ethylene Butylene Styrene Market. The development of advanced SEBS formulations with enhanced properties is likely to expand its application range. For instance, the introduction of high-performance SEBS grades that offer improved thermal stability and UV resistance is expected to attract interest from various sectors, including automotive and consumer goods. Market data indicates that the introduction of these innovative products could lead to a market growth rate of around 6% over the next few years. This evolution in polymer technology not only enhances the performance of SEBS but also positions it as a preferred choice in competitive markets.

Rising Demand in Construction Sector

The Styrene Ethylene Butylene Styrene Market is experiencing a notable surge in demand driven by the construction sector. As urbanization accelerates, the need for durable and flexible materials in construction applications becomes increasingly critical. Styrene Ethylene Butylene Styrene (SEBS) is favored for its excellent mechanical properties and resistance to environmental stress, making it suitable for various construction materials. In 2025, the construction industry is projected to account for a significant share of the SEBS market, with estimates suggesting a growth rate of approximately 5% annually. This trend indicates a robust potential for SEBS in applications such as sealants, adhesives, and roofing materials, thereby enhancing its market presence.

Expanding Applications in Medical Devices

The Styrene Ethylene Butylene Styrene Market is experiencing growth due to expanding applications in the medical device sector. SEBS is recognized for its biocompatibility and flexibility, making it suitable for various medical applications, including tubing, seals, and gaskets. The increasing demand for medical devices, driven by an aging population and advancements in healthcare technology, is expected to propel the SEBS market forward. Market analysis indicates that the medical sector could account for a substantial portion of SEBS consumption, with a projected growth rate of approximately 8% in the coming years. This trend underscores the importance of SEBS in meeting the evolving needs of the healthcare industry.

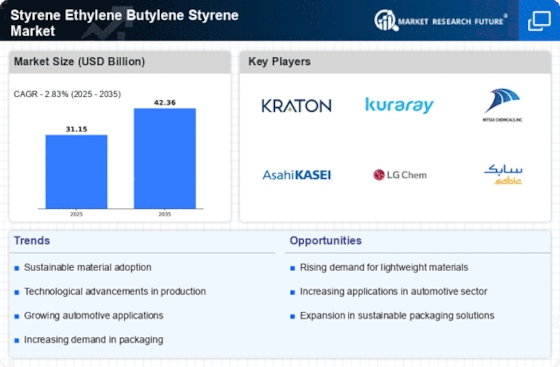

Increased Focus on Eco-Friendly Materials

The Styrene Ethylene Butylene Styrene Market is witnessing a shift towards eco-friendly materials, driven by heightened environmental awareness. Manufacturers are increasingly seeking sustainable alternatives to traditional plastics, and SEBS, with its recyclable properties, is emerging as a viable option. The market for eco-friendly SEBS is projected to grow significantly, with estimates suggesting a compound annual growth rate of 7% through 2025. This trend is further supported by regulatory frameworks promoting the use of sustainable materials across various industries. As companies strive to meet sustainability goals, the demand for SEBS in applications such as packaging and consumer products is likely to increase, thereby bolstering its market position.