Market Analysis

In-depth Analysis of Specialty Films Market Industry Landscape

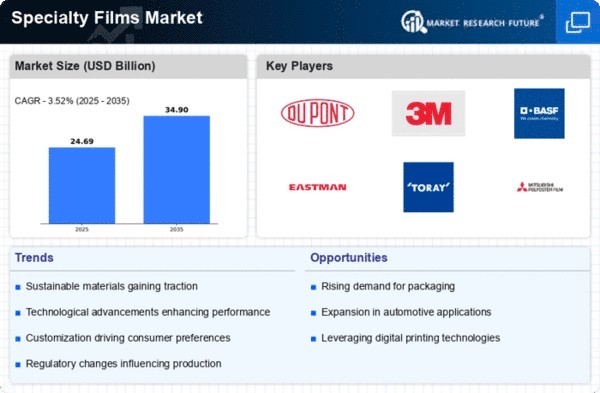

The Specialty Films Market is subject to a diverse array of dynamic factors that collectively shape its growth, trends, and competitive landscape. Here's an exploration of the key market dynamics shaping the Specialty Films Market, presented in a paragraph with a pointer format:

Diverse End-Use Applications:

The Specialty Films Market exhibits versatility in catering to diverse end-use applications across industries. From packaging and automotive to electronics and construction, specialty films find extensive use due to their unique properties, including barrier protection, optical clarity, and thermal resistance. Packaging Industry as a Key Driver:

The packaging industry emerges as a significant driver for the Specialty Films Market. The demand for specialty films in flexible packaging, labels, and shrink wraps is fueled by consumer preferences for visually appealing and convenient packaging solutions, contributing to the market's robust growth. Technological Advancements in Film Manufacturing:

Continuous technological advancements drive innovation in film manufacturing processes. Specialty film manufacturers focus on enhancing properties such as strength, flexibility, and surface characteristics, utilizing advanced technologies to meet the evolving requirements of end-use industries. Rising Demand for Biodegradable Films:

The market witnesses a rising demand for biodegradable and environmentally friendly specialty films. Consumer awareness of sustainability prompts the adoption of films made from biopolymers and recyclable materials, aligning with global initiatives for reduced environmental impact. Growth in Electronics and Display Applications:

Specialty films play a crucial role in electronics and display applications. With the proliferation of smartphones, tablets, and other electronic devices, the market experiences heightened demand for films with features like anti-glare coatings, touch sensitivity, and enhanced display clarity. Focus on High-Performance Barrier Films:

There is a growing focus on high-performance barrier films in the Specialty Films Market. Barrier films with excellent oxygen, moisture, and UV protection properties find applications in food packaging, pharmaceuticals, and electronics, driving the market's expansion. Globalization and Emerging Market Opportunities:

The globalization of industries and the exploration of emerging market opportunities contribute to the growth of the Specialty Films Market. Companies seek to tap into markets experiencing industrial growth and increased demand for advanced packaging and specialty film applications. Fluctuations in Raw Material Prices:

The market is susceptible to fluctuations in raw material prices, particularly those related to petrochemical derivatives. Variations in the costs of key ingredients impact production costs, influencing product pricing and overall market competitiveness. Innovations in Specialty Film Additives:

Continuous innovations in specialty film additives influence market dynamics. Additives such as antimicrobial agents, anti-fog agents, and UV stabilizers are incorporated to enhance film properties and cater to specific industry needs, fostering innovation within the market. Customization for Specific End-User Requirements:

Specialty film manufacturers focus on customization to meet specific end-user requirements. Films are tailored for unique applications, such as medical packaging, automotive interiors, and electronic displays, ensuring that specialty films address the specific challenges and needs of diverse industries. Impact of the COVID-19 Pandemic:

The Specialty Films Market faced challenges due to the COVID-19 pandemic. Disruptions in supply chains, changes in consumer behavior, and shifts in manufacturing priorities influenced market dynamics, requiring adaptability and resilience from industry players. Collaborations and Strategic Partnerships:

Collaborations and strategic partnerships are common in the Specialty Films Market's value chain. Film manufacturers, raw material suppliers, and end-users collaborate to optimize production processes, enhance material properties, and address challenges related to supply chain dynamics. Focus on Flexible Packaging Solutions:

The market sees a significant focus on flexible packaging solutions. Specialty films play a crucial role in the flexible packaging industry, providing benefits such as extended shelf life, enhanced product visibility, and improved printability, contributing to the growth of the market. Regulatory Compliance and Standards:

Adherence to regulatory compliance and industry standards is vital in the Specialty Films Market. Manufacturers must ensure that specialty films meet regulatory requirements for food contact, safety, and environmental considerations, maintaining product integrity and market acceptance.

Leave a Comment