Government Initiatives and Support

Government initiatives in South Korea are significantly influencing the machine vision market. The South Korean government has launched various programs aimed at promoting smart factories and Industry 4.0 technologies. These initiatives include financial incentives, grants, and tax benefits for companies investing in automation and machine vision systems. In 2025, it is estimated that government funding for automation technologies will exceed $300 million, further stimulating market growth. By fostering a conducive environment for technological advancement, the government is encouraging local businesses to adopt machine vision solutions, thereby enhancing operational efficiency and product quality. This support is likely to accelerate the adoption of machine vision technologies across various sectors, solidifying their importance in the industrial ecosystem.

Growing Adoption in Emerging Industries

The machine vision market is experiencing growing adoption in emerging industries within South Korea. Sectors such as robotics, agriculture, and logistics are increasingly recognizing the value of machine vision technologies for enhancing operational efficiency. For instance, in agriculture, machine vision systems are utilized for crop monitoring and quality assessment, while in logistics, they facilitate automated sorting and inventory management. By 2025, the market share of machine vision applications in these emerging sectors is projected to increase by approximately 20%. This trend suggests a diversification of the machine vision market, as it expands beyond traditional manufacturing applications. As these industries continue to evolve, the demand for machine vision solutions is likely to rise, further solidifying their role in driving innovation and efficiency.

Increased Focus on Safety and Compliance

The machine vision market is witnessing a heightened focus on safety and compliance in South Korea. Industries are increasingly required to adhere to stringent safety regulations and quality standards, particularly in sectors such as food and pharmaceuticals. Machine vision systems play a pivotal role in ensuring compliance by automating inspection processes and reducing human error. In 2025, the market for machine vision solutions aimed at safety compliance is projected to grow by approximately 15%, driven by the need for reliable quality assurance. This trend indicates a shift towards integrating machine vision technologies as essential tools for maintaining safety standards, thereby enhancing the overall integrity of production processes. As companies prioritize compliance, the machine vision market is likely to expand, offering innovative solutions tailored to meet regulatory requirements.

Rising Demand for Advanced Manufacturing

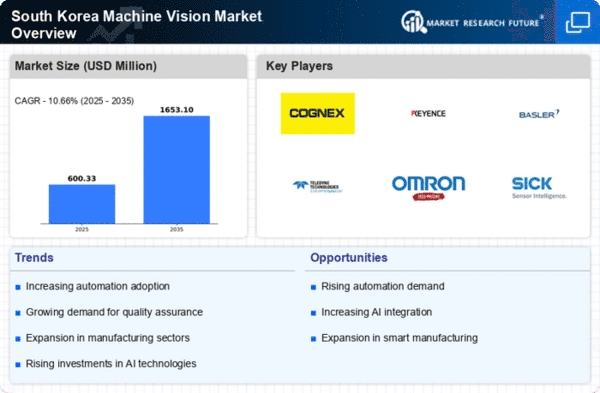

The machine vision market in South Korea is experiencing a notable surge in demand due to the country's emphasis on advanced manufacturing techniques. As industries increasingly adopt automation, the need for precise quality inspection and process control becomes paramount. In 2025, the market is projected to reach approximately $1.5 billion, reflecting a growth rate of around 12% annually. This trend is driven by sectors such as electronics, automotive, and pharmaceuticals, where machine vision systems enhance productivity and reduce operational costs. The integration of high-resolution cameras and sophisticated algorithms allows manufacturers to detect defects and ensure compliance with stringent quality standards. Consequently, the machine vision market is positioned to play a critical role in the evolution of South Korea's manufacturing landscape, fostering innovation and competitiveness.

Technological Advancements in Imaging Systems

Technological advancements in imaging systems are propelling the machine vision market forward in South Korea. Innovations such as 3D imaging, hyperspectral imaging, and deep learning algorithms are enhancing the capabilities of machine vision systems. These advancements enable more accurate defect detection and analysis, which is crucial for industries that demand high precision. In 2025, the market for advanced imaging technologies is expected to account for over 40% of the total machine vision market, reflecting a growing preference for sophisticated solutions. As companies seek to improve their operational efficiency and product quality, the adoption of these advanced imaging systems is likely to increase. This trend underscores the importance of continuous innovation in the machine vision market, as businesses strive to remain competitive in a rapidly evolving technological landscape.