Market Trends

Key Emerging Trends in the Smart Pneumatics Market

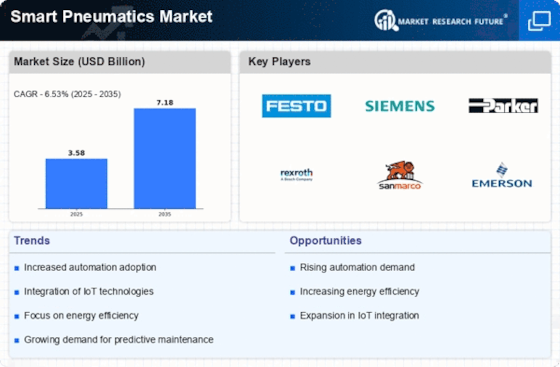

The trajectory of the smart pneumatics market is shaped by several notable trends that have influenced preferences across different industries globally. One example of these has been seen in industrial Internet of Things (IIoT) technologies that are increasingly being adopted around the world. They feature a series of pneumatic systems, which make them part of a connected industrial ecosystem for real-time monitoring, data analytics, and remote control enabled by them. Another trend that is common throughout the smart pneumatics industry is energy efficiency due to growing environmental concerns globally. With the focus now shifting towards sustainable practices globally, manufacturers and industries continue to search for pneumatic solutions that optimize energy consumption while still delivering high-performance levels required by various applications areas like traditional manufacturing operations or machine building sectors as well as emerging ones such as process plants where compressed air is used extensively for actuation purposes in combination with other equipment like solenoid valves, etc. For instance, companies are going green with smarter choices like using energy-efficient components, including valves and sensors in their products, so as to meet regulatory standards set forth by governments concerned over carbon emissions. Maintenance practices within industries are being reshaped by the rise of predictive maintenance, in which smart pneumatics play a huge role. These systems can detect potential problems before they become critical through embedded sensors and real-time monitoring capability, enabling preventative measures to be taken rather than following reactive ones and then requiring immediate attention when there are any issues with these machines. Consequently, more devices started to interact with each other, therefore made us think about new opportunities for smart pneumatics that should perfectly integrate into virtually any automated system or robotic line anywhere in the industry around the globe, such as packaging applications where one might find a variety different types like those used on production lines of consumer goods producers while others are utilized within heavy manufacturing plants like steel mills; together these two examples illustrate how broad-ranging demands exist among customers seeking highly specialized products which can still be universally implemented across multiple processes satisfying all needs simultaneously without sacrificing quality standards whatsoever. Additionally, significant steps have been taken toward integrating Artificial Intelligence (AI) and machine learning functionalities into smart pneumatics. By harnessing sophisticated AI and ML algorithms capable of processing massive amounts of data generated by pneumatic systems, these advanced technologies improve decision-making processes related to operation optimization, for example, predictive maintenance purposes that involve running simulations based on predicted operational states instead of relying only upon past experiences during design phase being aware this will help optimize energy consumption levels while minimizing downtime yet maximizing productivity over longer periods leading towards efficient manufacturing operations due better utilization resources.

Leave a Comment