- Global Market Outlook

- In-depth analysis of global and regional trends

- Analyze and identify the major players in the market, their market share, key developments, etc.

- To understand the capability of the major players based on products offered, financials, and strategies.

- Identify disrupting products, companies, and trends.

- To identify opportunities in the market.

- Analyze the key challenges in the market.

- Analyze the regional penetration of players, products, and services in the market.

- Comparison of major players’ financial performance.

- Evaluate strategies adopted by major players.

- Recommendations

- Vigorous research methodologies for specific market.

- Knowledge partners across the globe

- Large network of partner consultants.

- Ever-increasing/ Escalating data base with quarterly monitoring of various markets

- Trusted by fortune 500 companies/startups/ universities/organizations

- Large database of 5000+ markets reports.

- Effective and prompt pre- and post-sales support.

Market Size Snapshot

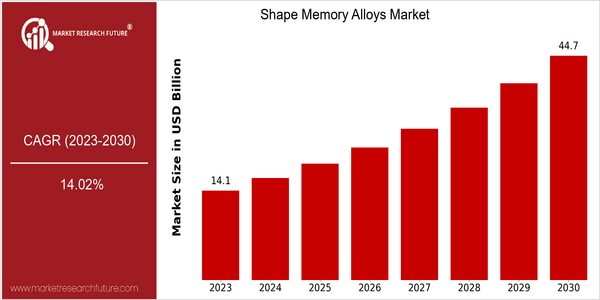

| Year | Value |

|---|---|

| 2023 | USD 14.1 Billion |

| 2030 | USD 44.68 Billion |

| CAGR (2023-2030) | 14.02 % |

Note – Market size depicts the revenue generated over the financial year

The Shape Memory Alloys (SMAs) market is poised for significant growth, with the current market size estimated at USD 14.1 billion in 2023 and projected to reach USD 44.68 billion by 2030. This remarkable growth trajectory reflects a compound annual growth rate (CAGR) of 14.02% over the forecast period. The increasing demand for SMAs across various industries, including aerospace, automotive, and healthcare, is a primary driver of this expansion. Technological advancements, such as the development of new alloy compositions and enhanced manufacturing processes, are further propelling market growth by improving the performance and applicability of SMAs in diverse applications. Key players in the Shape Memory Alloys market, such as Johnson Matthey, SAES Getters, and Fort Wayne Metals, are actively engaging in strategic initiatives to capitalize on this growth. These companies are investing in research and development to innovate SMA products and are forming partnerships to expand their market reach. For instance, collaborations aimed at integrating SMAs into next-generation medical devices and smart materials are indicative of the industry's forward momentum. As the market continues to evolve, the interplay of technological innovation and strategic business maneuvers will be crucial in shaping the future landscape of the Shape Memory Alloys market.

Regional Market Size

Regional Deep Dive

The Shape Memory Alloys (SMAs) market is experiencing significant growth across various regions, driven by advancements in material science and increasing applications in sectors such as aerospace, automotive, and healthcare. In North America, the market is characterized by a strong presence of key players and a robust research and development ecosystem, while Europe is witnessing innovations in SMA technologies, particularly in medical devices. The Asia-Pacific region is rapidly emerging as a manufacturing hub, leveraging cost advantages and growing demand in industrial applications. Meanwhile, the Middle East and Africa are gradually adopting SMAs, influenced by infrastructural developments, and Latin America is exploring the potential of SMAs in various sectors, albeit at a slower pace due to economic challenges.

Europe

- The European Union has introduced regulations promoting the use of advanced materials, including SMAs, in automotive and aerospace sectors, encouraging innovation and sustainability.

- Research institutions in Germany and France are collaborating on projects to develop next-generation SMAs with improved properties, which are expected to enhance their application in various industries.

Asia Pacific

- Japan is leading in SMA research, with companies like Mitsubishi and Toyota investing in the development of SMAs for robotics and automotive applications, which is expected to drive market growth.

- China's rapid industrialization and focus on smart manufacturing are creating a surge in demand for SMAs, particularly in the electronics and automotive sectors.

Latin America

- Brazil is beginning to explore the use of SMAs in the automotive sector, with local manufacturers looking to enhance vehicle performance and safety features.

- Regulatory frameworks in countries like Mexico are slowly evolving to support the adoption of advanced materials, including SMAs, in various industries.

North America

- The U.S. Department of Defense has been investing in SMA technologies for military applications, enhancing the performance and durability of equipment used in extreme conditions.

- Companies like Nitinol Devices & Components are pioneering the use of SMAs in medical devices, particularly in stents and guidewires, which are revolutionizing minimally invasive surgeries.

Middle East And Africa

- The UAE is investing in smart city projects that incorporate SMA technologies for infrastructure and construction, aiming to enhance the resilience and efficiency of buildings.

- South Africa is exploring the use of SMAs in mining equipment to improve safety and operational efficiency, reflecting a growing interest in advanced materials in the region.

Did You Know?

“Shape Memory Alloys can return to their original shape after being deformed, a property that is utilized in various applications, from self-expanding stents to actuators in robotics.” — Materials Science and Engineering Reports

Segmental Market Size

The Shape Memory Alloys (SMAs) segment plays a crucial role in various industries, particularly in aerospace, automotive, and biomedical applications, and is currently experiencing stable growth. Key drivers of demand include the increasing need for lightweight materials that enhance energy efficiency and performance, as well as advancements in manufacturing technologies that enable the production of complex SMA components. Regulatory policies promoting the use of innovative materials in safety-critical applications further bolster this segment's appeal. Currently, the adoption of SMAs is in the scaled deployment stage, with companies like Boeing and NASA leading the way in aerospace applications, while the automotive sector sees significant interest from manufacturers like Ford and General Motors. Primary use cases include actuators in aerospace systems, stents in medical devices, and adaptive components in automotive systems. Trends such as the push for sustainability and the integration of smart materials in consumer products are accelerating growth, while technologies like 3D printing and advanced alloy compositions are shaping the evolution of SMAs, enabling more efficient and versatile applications.

Future Outlook

The Shape Memory Alloys (SMAs) market is poised for significant growth from 2023 to 2030, with a projected market value increase from $14.1 billion to $44.68 billion, reflecting a robust compound annual growth rate (CAGR) of 14.02%. This growth trajectory is driven by the increasing adoption of SMAs across various industries, including aerospace, automotive, healthcare, and robotics. As industries seek to enhance performance and efficiency, the unique properties of SMAs—such as their ability to return to a predetermined shape upon heating—are becoming increasingly valuable. By 2030, it is anticipated that the penetration of SMAs in the automotive sector alone could reach upwards of 25%, driven by advancements in lightweight materials and energy-efficient designs. Key technological drivers, such as the development of new SMA compositions and manufacturing techniques, are expected to further propel market growth. Innovations in 3D printing and additive manufacturing are enabling more complex designs and applications, particularly in the medical field, where SMAs are being utilized in stents and orthopedic devices. Additionally, supportive government policies aimed at promoting sustainable materials and energy-efficient technologies are likely to create a favorable environment for SMA adoption. Emerging trends, including the integration of SMAs in smart materials and systems, will also play a crucial role in shaping the market landscape, positioning SMAs as a cornerstone of future technological advancements.

Covered Aspects:| Report Attribute/Metric | Details |

|---|---|

| Market Size Value In 2022 | USD 13.87 Billion |

| Market Size Value In 2023 | USD 14.1 Billion |

| Growth Rate | 14.02% (2023-2030) |

Shape Memory Alloys Market Highlights:

Leading companies partner with us for data-driven Insights

Kindly complete the form below to receive a free sample of this Report

Tailored for You

- Dedicated Research on any specifics segment or region.

- Focused Research on specific players in the market.

- Custom Report based only on your requirements.

- Flexibility to add or subtract any chapter in the study.

- Historic data from 2014 and forecasts outlook till 2040.

- Flexibility of providing data/insights in formats (PDF, PPT, Excel).

- Provide cross segmentation in applicable scenario/markets.