Market Share

Sand Control Systems Market Share Analysis

There are different approaches for enhancing the function of a well to a lower level of sand production. The options extend from relatively low-cost measures including operational modifications to premium emendations including sand consolidation or gravel packing. The given sentence has been successfully humanized. The sand control method recommended depends on site-specific conditions, the entire operation process, and economic considerations.

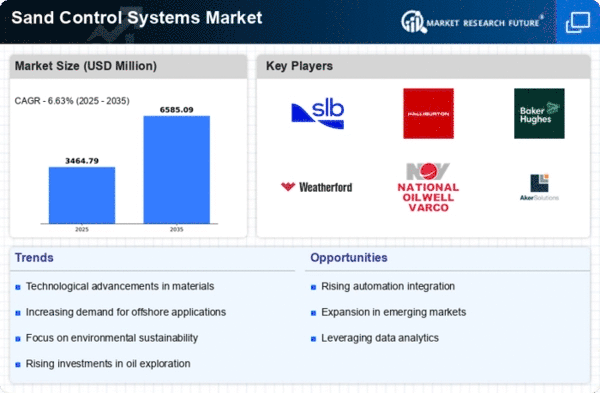

The sand control systems market is dynamic and it is estimated that the market will have expected growth rate over the near future as well. Sands control systems market has become more desired by the biggest oil producers as a means of keeping output stable from the active oil fields in periods of unpredictable oil prices. Indeed, due to the constant technological advancements and growing demands within the oil and gas sector, sand control systems market is undergoing some profound transformations. Among the critical trends in this market relates to the evolution of complex sand control technology through which manufacturers innovate the technique and systems. The demand for more efficient and hardy sand control solutions with the prospect of rising drilling activities from challenging reservoirs that suffers from sand production acceleration is almost done. Specialized techniques such as sand screens, shale permeability reduction chemical injection, and downhole tools have joined forces with the main reliable methods of keeping sand out and safeguarding well integrity, thus allowing uninterrupted hydrocarbons production.

An integrated sand control solution is also being developed by the market as the trend is towards integrated sand control solution. Organizations are developing an integrated sand control units which is made up of different tools and technological advancements appropriate for distinct well performance as well as services. A case where joint solutions reduce operations, check efficiency, and offer targeted approaches to the sand production issues across the sand production regions that are alternated and tailored to sand control in the industry is presented.

These in addition to, the adoption of intelligent sand control systems has also become a substantial trend. These systems get on with sensor technology, data analytics, and automation to keep a close watch on the well status in real time and give the early warning of sand production problems and take autonomic actions under these circumstances. The ability of intelligent systems to implement preventive measures due to the change of downhole conditions, satisfying sand control and minimization of downtime, is an indication of the industry shift towards more installment of the "smart" systems with increased efficiency and effectiveness of the oil and gas operations.

Furthermore, there is a new wave of system that is giving the weight to environmentally conscientious and sustainable sand control options. Companies are on the mission to discover sustainably obtained materials and chemicals that have no impact on nature at the same time they are up to the task. Sustainable approaches of sand control systems intend to reduce environmental effect, elevate operational sustainability, and gain the industry leniency so as to reflect the industry’s commitment to ethical and environmental friendly operations.

Leave a Comment