Technological Innovations

Technological advancements play a pivotal role in shaping the Rotary Blasthole Drilling Rig Market. Innovations such as automation, remote monitoring, and advanced drilling techniques are enhancing operational efficiency and safety. For instance, the integration of artificial intelligence and machine learning in drilling operations is enabling real-time data analysis, which optimizes drilling parameters and minimizes downtime. Furthermore, the introduction of hybrid and electric drilling rigs is addressing environmental concerns while improving fuel efficiency. As these technologies continue to evolve, they are expected to drive the market forward, with estimates suggesting that the adoption of advanced drilling technologies could increase productivity by up to 30%. This trend indicates a promising future for the Rotary Blasthole Drilling Rig Market as it adapts to the changing landscape of mining operations.

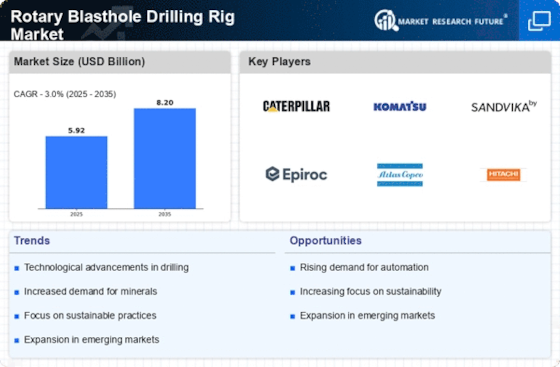

Increased Demand for Minerals

The Rotary Blasthole Drilling Rig Market is experiencing heightened demand for minerals, driven by the growing need for raw materials in various sectors, including construction and manufacturing. As economies expand, the extraction of minerals such as copper, gold, and lithium becomes increasingly critical. This trend is underscored by projections indicating that the mining sector is expected to grow at a compound annual growth rate of approximately 5.5% over the next several years. Consequently, the demand for efficient and reliable drilling rigs is likely to surge, as companies seek to enhance productivity and reduce operational costs. The Rotary Blasthole Drilling Rig Market is thus positioned to benefit from this upward trajectory, as mining companies invest in advanced drilling technologies to meet the escalating mineral requirements.

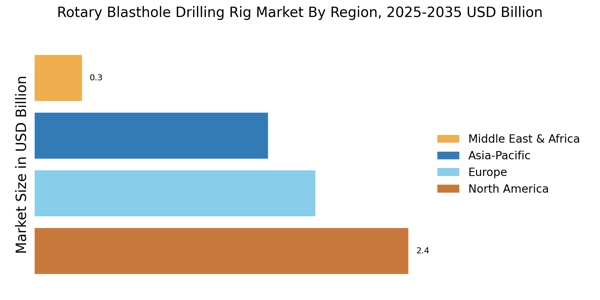

Rising Infrastructure Development

Infrastructure development is a key driver of the Rotary Blasthole Drilling Rig Market. As nations invest in large-scale infrastructure projects, the demand for minerals and aggregates used in construction is on the rise. This trend is particularly evident in emerging economies, where urbanization and industrialization are accelerating. The construction of roads, bridges, and buildings necessitates the extraction of various minerals, thereby increasing the need for efficient drilling solutions. Market analysts project that the infrastructure sector will witness substantial growth, with investments expected to reach trillions of dollars in the coming years. Consequently, the Rotary Blasthole Drilling Rig Market stands to benefit from this surge in infrastructure projects, as companies seek reliable drilling rigs to support their operations.

Strategic Partnerships and Collaborations

Strategic partnerships and collaborations are becoming increasingly prevalent within the Rotary Blasthole Drilling Rig Market. Companies are recognizing the value of joining forces to enhance their technological capabilities and expand their market reach. Collaborations between drilling rig manufacturers and technology providers are particularly noteworthy, as they facilitate the development of innovative solutions that address the evolving needs of the mining sector. These partnerships can lead to the sharing of resources, knowledge, and expertise, ultimately resulting in improved product offerings. Furthermore, such alliances may enable companies to penetrate new markets and diversify their portfolios. As the industry continues to evolve, the trend of strategic collaborations is likely to play a crucial role in shaping the future of the Rotary Blasthole Drilling Rig Market.

Regulatory Compliance and Safety Standards

The Rotary Blasthole Drilling Rig Market is significantly influenced by stringent regulatory compliance and safety standards imposed by governments and industry bodies. These regulations are designed to ensure safe mining practices and minimize environmental impact. As a result, mining companies are compelled to invest in modern drilling rigs that meet these standards, thereby driving demand for advanced technologies. The market is witnessing a shift towards rigs equipped with enhanced safety features, such as automatic shut-off systems and improved ventilation mechanisms. This trend is likely to continue, as compliance with safety regulations not only protects workers but also enhances operational efficiency. The Rotary Blasthole Drilling Rig Market is thus expected to grow as companies prioritize safety and sustainability in their operations.