Expansion of E-commerce and Logistics

The rapid expansion of e-commerce and logistics sectors is significantly influencing the Robotic Flexible Part Feeding System Market. As online shopping continues to grow, the need for efficient sorting, packing, and distribution systems has become paramount. Robotic flexible part feeding systems are increasingly utilized in warehouses and fulfillment centers to automate these processes. Recent statistics indicate that the e-commerce sector is expected to reach trillions in revenue, prompting companies to invest in automation technologies. This shift not only enhances operational efficiency but also reduces labor costs and improves order accuracy. The Robotic Flexible Part Feeding System Market is thus poised to capitalize on this trend, as businesses seek innovative solutions to meet the demands of a rapidly evolving retail landscape.

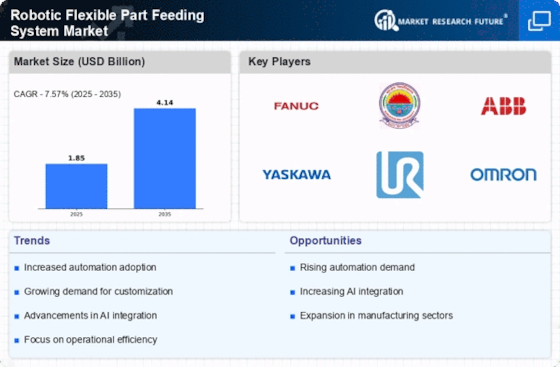

Increased Automation in Manufacturing

The rise of automation in manufacturing processes is a pivotal driver for the Robotic Flexible Part Feeding System Market. As industries strive for efficiency and productivity, the demand for robotic systems that can adapt to various tasks has surged. According to recent data, the automation market is projected to grow significantly, with a compound annual growth rate of over 10% in the coming years. This trend indicates a strong inclination towards integrating robotic solutions that enhance operational capabilities. The Robotic Flexible Part Feeding System Market is positioned to benefit from this shift, as manufacturers seek systems that can handle diverse components and streamline production lines. Consequently, the ability of these systems to improve throughput and reduce labor costs makes them increasingly attractive to manufacturers across various sectors.

Technological Advancements in Robotics

Technological advancements in robotics are a key driver for the Robotic Flexible Part Feeding System Market. Innovations in sensor technology, artificial intelligence, and machine learning are enhancing the capabilities of robotic systems, making them more adaptable and efficient. These advancements allow for improved recognition and handling of various parts, which is essential for flexible manufacturing environments. Market trends indicate that investments in robotics technology are on the rise, with companies seeking to leverage these innovations to gain a competitive edge. The Robotic Flexible Part Feeding System Market stands to benefit from these developments, as manufacturers increasingly adopt advanced robotic solutions to optimize their production processes and respond to changing market demands.

Rising Labor Costs and Skills Shortages

Rising labor costs and skills shortages are compelling factors driving the Robotic Flexible Part Feeding System Market. As labor markets tighten and wages increase, manufacturers are seeking cost-effective solutions to maintain profitability. Robotic flexible part feeding systems offer a viable alternative by automating repetitive tasks, thereby reducing reliance on manual labor. Furthermore, the shortage of skilled workers in various regions is prompting companies to invest in automation technologies that can operate with minimal human intervention. This trend suggests a growing recognition of the need for efficient and reliable systems that can address labor challenges. The Robotic Flexible Part Feeding System Market is likely to see increased adoption as businesses strive to enhance productivity while managing labor-related constraints.

Growing Demand for Precision and Quality

The need for precision and quality in manufacturing processes is driving the Robotic Flexible Part Feeding System Market. As industries such as automotive, electronics, and pharmaceuticals demand higher standards, the role of robotic feeding systems becomes crucial. These systems are designed to ensure accurate placement and handling of parts, which is essential for maintaining product quality. Market analysis suggests that the demand for high-precision components is expected to rise, with a notable increase in investments in advanced manufacturing technologies. This trend indicates that companies are prioritizing quality control, thereby enhancing the relevance of robotic flexible part feeding systems. The ability of these systems to minimize errors and improve consistency positions them as vital tools in achieving manufacturing excellence.