Market Trends

Key Emerging Trends in the Rigid Plastic Packaging Market

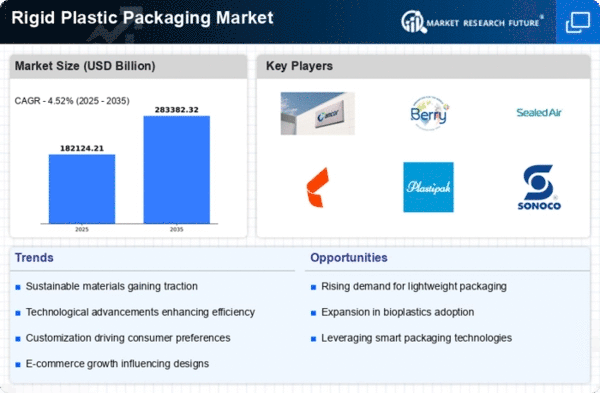

The significant transformation experienced regarding consumer preferences, technological advances and sustainability concerns explains why there are currently new trends that have emerged when looking at how people respond towards those preferences within this dynamic context as far as rigid plastic packaging industry’s concerns are concerned. Recently, we got to see a noticeable increase on demand for rigid plastic packaging driven by its multiple functions which cut across various industries including healthcare delivery systems; personal care services or even foodstuff processing plants among others.

One notable trend shaping this industry is sustainability (One prominent trend). As awareness continues about environmental concerns keeps growing among both consumers and industries, individuals prefer eco-friendly packages than before.

Moreover, adoption of innovative technologies is a major driver of market dynamics (This has resulted to technology which plays a key role on how markets behave.). Advanced manufacturing techniques such as blow molding and injection molding have ensured that there are intricate designs made specifically for different industries. These technological developments plus increased production efficiency, lower manufacturing costs as well as an overall improvement in the quality of rigid plastics amongst other things contribute towards increased productivity in this industry. On top of that, e-commerce is emerging as one of the largest contributors to market growth. E-commerce has driven demand for robust protective packaging materials. Rigorous protection properties (but it is also strong) have made rigid plastic packagings more preferred choices by many companies operating in this area including shipping companies worldwide. This trend will probably maintain its pace with the fast growing global e-commerce trade.

The food and beverages industry is one of the biggest consumers of rigid plastic packaging, which we don’t see changing anytime soon (This implies that this trend will not change).. Rigid plastics are known for their convenience because they are lighter or less heavy hence easy to package different foods as well as beverages ( convenience). Additionally, firms have adopted modern packaging designs such as tamper evident features or open lids used on containers where food or drink items can be kept thus enhancing attractiveness at some point during its life cycle especially before disposal stage.

Leave a Comment