Top Industry Leaders in the Rigid Plastic Packaging Market

The rigid plastic packaging market, encompassing sturdy containers and bottles made from plastic, is a bustling arena of competition. Players of all sizes vie for market share, showcasing their strength and resilience in a landscape driven by innovation, sustainability, and cost-effectiveness. Let's delve into this dynamic ecosystem, dissecting the key strategies, market share determinants, and recent developments shaping its trajectory.

The rigid plastic packaging market, encompassing sturdy containers and bottles made from plastic, is a bustling arena of competition. Players of all sizes vie for market share, showcasing their strength and resilience in a landscape driven by innovation, sustainability, and cost-effectiveness. Let's delve into this dynamic ecosystem, dissecting the key strategies, market share determinants, and recent developments shaping its trajectory.

Strategies that Pack a Punch:

-

Innovation Titans: Industry giants like Amcor, Berry Global, and Aptar Pharma invest heavily in R&D, developing cutting-edge materials, designs, and functionalities. Think lightweight yet durable bottles, child-resistant caps, and intelligent packaging with integrated sensors. -

Cost-Conscious Contenders: Regional players like Huhtamaki and Taizhou Huangyan prioritize affordability, utilizing recycled materials and optimizing production processes to cater to price-sensitive segments and emerging markets. This strategy ensures they remain competitive in cost-driven sectors. -

Niche Experts: Smaller players carve out their niches by specializing in specific materials, like bioplastics, or targeting unique applications like medical or pharmaceutical packaging. This focused approach allows them to excel in specialized areas.

Factors that Determine Market Muscle:

-

Product Diversification: Offering a wide range of rigid plastic packaging formats, from bottles and jars to tubs and trays, caters to diverse needs across industries like food & beverage, cosmetics, and household products. This broadens the customer base and increases market share potential. -

Sustainability Focus: Consumer and regulatory pressure is pushing manufacturers towards eco-friendly options. This includes using recycled content, developing biodegradable or compostable materials, and minimizing packaging waste. Companies embracing this trend resonate with environmentally conscious consumers. -

Technological Advancements: Integrating smart features like anti-counterfeiting technology, temperature monitoring sensors, and QR codes enhances brand protection, product safety, and consumer engagement. This opens up new marketing and traceability opportunities. -

Regional Adaptations: Understanding cultural nuances and tailoring packaging designs to local preferences is crucial for success in specific markets. This includes factors like portion sizes, language usage, and aesthetic considerations.

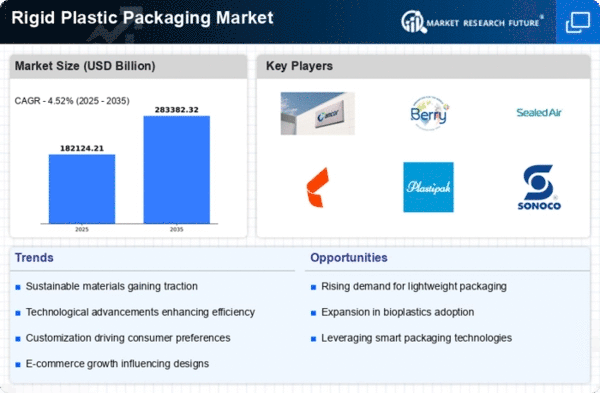

Key Players:

- Consolidated Container Company

- Amcor Limited

- LINPAC Packaging Limited

- Bemis Company

- Silgan Holdings

- RPC Group Plc

- Plastipak Holdings

- Inc

- Sealed Air Corporation

- Reynolds Group Holdings

- Berry Plastics Corporation.

Recent Developments:

October 2023: The Ellen MacArthur Foundation released its "Global Commitment 2025 Progress Report," indicating significant progress in the transition towards a circular economy for plastic packaging. However, the report also highlighted challenges in scaling up collection and recycling infrastructure, particularly in developing economies.

November 2023: The European Union implemented the Single-Use Plastics Directive, banning certain single-use plastic items like straws, cutlery, and cotton buds. This has led to increased demand for sustainable alternatives, including reusable and bio-based rigid plastic packaging.

In 2022, Amcor plc Amcor’s New Lightweighting Technology Introduced in a Quantum Leap for the Future of Packaging was launched on two steps lightweight technology, which eliminates over 50% of material at the final stage.

In June 2019, Amcor acquired Bemis Company Inc., a US-based flexible packager, at approximately USD5.25bn

October 2021, Pactiv Evergreen Inc., through its fully-owned subsidiary, Pactiv Evergreen Group, announced that it had come to an agreement to acquire Fabri-Kal as part of its growth strategy.

October 2022: Amcor Rigid Package (ARP) created a novel two-step lightweight method that eliminates more than 50% of the material and weight in the bottle finish, representing a quantum leap forward in packaging weight reduction. ARP's innovative QuantumTM technology for polyethylene terephthalate (PET) bottles gives sustainability benefits, lowers costs, and improves packaging aesthetics. ARP is a leader in developing technology that produces more sustainable packaging choices.

October 2021: Pactiv Inc. announced the acquisition of Fabri-Kal, a leading manufacturer of food service and consumer brand packaging solutions, through its wholly-owned subsidiary, Pactiv Evergreen Group Holdings Inc. Fabri-products Kal's for the consumer packaged goods and industrial food markets include portion cups, lids, clamshells, drink cups, and yogurt containers.

In November 2022, Sterimed, the leading global sterilization packaging material manufacturer, introduced its substantially rigid plastic packaging solution POLYBOND CGP 85GSM substrate dedicated especially to client needs. The launch represents another polymer-reinforced cellulose-based addition into the healthcare portfolio.

September 2022, Borealis and ITC Packaging have partnered together on the development of new & more sustainable primary food contact-packaging formats particularly suited to food-contact products. It is a leading European producer of lightweight packaging for contact with food.

In the whole United States, plastics increased to 125.5 billion pounds for 2022 from 123.9 billion pounds produced in 2021, as shown by the American Chemistry Council. As plastic production soars, demand for rigid plastic packaging is expected to rise with the growing availability of raw materials. In particular, higher polyethylene (PP) production, widely used in rigid packaging, is expected to increase availability and reduce prices in the supply of polypropylene resin for packaging manufacturers.

May 2023, LanzaTech and Plastipak Partner to Produce World’s First PET Resin Made from Waste Carbon.