Growth in Pharmaceutical Applications

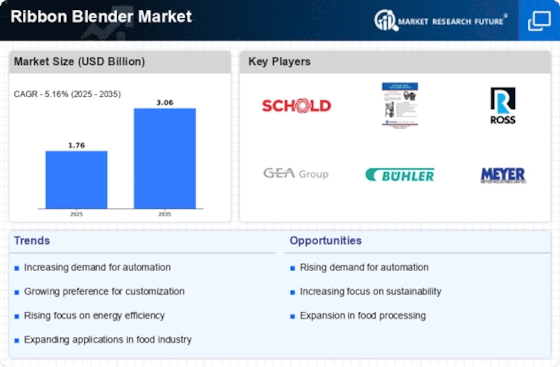

The Ribbon Blender Market is witnessing growth driven by increasing applications in the pharmaceutical sector. The need for precise and consistent mixing of powders and granules is paramount in pharmaceutical manufacturing, where product quality is critical. Ribbon blenders are particularly effective in achieving homogeneity in formulations, which is essential for the production of tablets and capsules. Recent statistics indicate that the pharmaceutical industry is one of the fastest-growing segments for ribbon blenders, with a projected increase in demand as companies strive to enhance their production processes. This trend highlights the importance of ribbon blenders in ensuring compliance with stringent regulatory standards, thereby reinforcing their role in the Ribbon Blender Market. As pharmaceutical companies continue to innovate, the demand for advanced mixing solutions is likely to rise.

Diverse Applications Across Industries

The Ribbon Blender Market benefits from its diverse applications across various sectors, including chemicals, cosmetics, and construction. This versatility allows ribbon blenders to cater to a wide range of mixing requirements, from heavy-duty applications to delicate formulations. The ability to handle different materials, such as powders, granules, and pastes, makes ribbon blenders indispensable in many manufacturing processes. Recent market analyses indicate that the demand for ribbon blenders is expanding as industries recognize the advantages of using these machines for efficient mixing. This trend is likely to continue, as companies seek to optimize their production lines and improve product quality. Consequently, the Ribbon Blender Market is expected to thrive, driven by the increasing need for adaptable and efficient mixing solutions across multiple sectors.

Sustainability and Eco-Friendly Practices

The Ribbon Blender Market is increasingly influenced by sustainability and eco-friendly practices. As industries face pressure to reduce their environmental footprint, manufacturers are seeking equipment that aligns with these goals. Ribbon blenders, known for their energy efficiency and minimal waste generation, are becoming a preferred choice for companies aiming to adopt greener practices. The shift towards sustainable production methods is prompting investments in ribbon blending technology that not only meets operational needs but also adheres to environmental standards. Furthermore, the emphasis on using recyclable and biodegradable materials in product formulations is driving the demand for efficient mixing solutions. This trend suggests that the Ribbon Blender Market will continue to evolve, with a focus on sustainability as a key driver of innovation and growth.

Rising Demand from Food and Beverage Sector

The Ribbon Blender Market is significantly influenced by the rising demand from the food and beverage sector. As consumer preferences shift towards processed and convenience foods, manufacturers are compelled to enhance their production capabilities. Ribbon blenders are particularly favored for their ability to handle a wide range of ingredients, from powders to granules, ensuring uniformity in product quality. According to recent data, the food and beverage sector accounts for a substantial share of the ribbon blender market, with projections indicating a steady growth rate. This demand is further fueled by the need for efficient mixing solutions that can accommodate various formulations, thereby driving investments in ribbon blending technology. Consequently, the Ribbon Blender Market is poised for expansion as food manufacturers seek to improve their operational efficiency and product offerings.

Technological Advancements in Mixing Equipment

The Ribbon Blender Market is experiencing a notable transformation due to rapid technological advancements. Innovations in design and functionality are enhancing the efficiency of ribbon blenders, allowing for more uniform mixing and reduced processing times. For instance, the integration of automation and smart technology is streamlining operations, which is particularly beneficial in sectors such as food processing and pharmaceuticals. The introduction of advanced materials is also contributing to the durability and performance of these machines. As a result, manufacturers are increasingly investing in state-of-the-art ribbon blenders to meet the growing demand for high-quality mixing solutions. This trend is expected to drive the Ribbon Blender Market forward, as companies seek to optimize their production processes and improve product consistency.