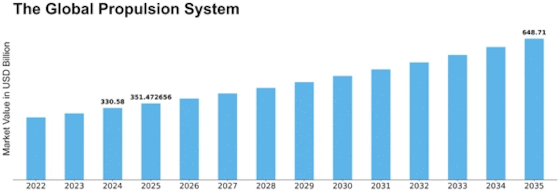

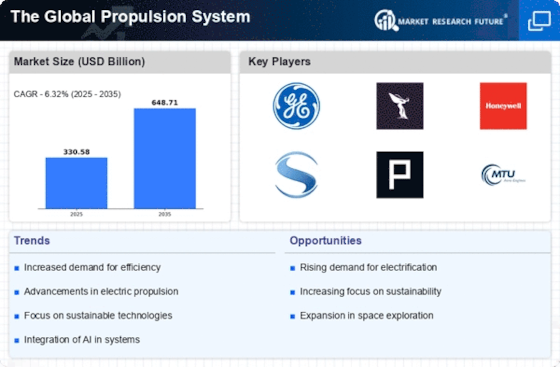

Propulsion System Size

Propulsion System Market Growth Projections and Opportunities

The propulsion system market is significantly influenced by various factors that drive its growth and evolution. One crucial factor is the increasing demand for efficient, reliable, and environmentally friendly propulsion solutions across various industries, including aerospace, automotive, marine, and defense. As industries strive to improve fuel efficiency, reduce emissions, and comply with stringent environmental regulations, there is a growing need for propulsion systems that offer advanced technologies, such as electric propulsion, hybrid propulsion, and alternative fuels, to meet sustainability goals and address climate change concerns. Additionally, as the global population grows, urbanization increases, and mobility preferences evolve, there is a growing demand for propulsion systems that offer increased performance, range, and versatility to support diverse transportation needs and applications.

Moreover, technological advancements play a crucial role in shaping the propulsion system market. Advances in materials science, aerodynamics, combustion technologies, and power electronics enable the development of next-generation propulsion systems that offer improved efficiency, performance, and reliability. Electric propulsion systems, including electric motors, batteries, and power management systems, are becoming increasingly prevalent in various industries, offering benefits such as reduced emissions, lower operating costs, and quieter operation compared to traditional internal combustion engines. Additionally, advancements in hybrid propulsion technologies, such as plug-in hybrid electric systems and fuel-cell hybrids, offer a transitionary step towards full electrification while providing increased range and flexibility for long-distance travel and heavy-duty applications.

Furthermore, regulatory frameworks and policy initiatives significantly influence market dynamics in the propulsion system sector. Governments around the world are implementing measures to promote clean energy technologies, reduce greenhouse gas emissions, and accelerate the transition towards sustainable transportation systems. This includes regulatory mandates, such as fuel economy standards, emissions regulations, and incentives for electric vehicles (EVs), that drive market demand for advanced propulsion systems that offer reduced environmental impact and comply with regulatory requirements. Additionally, government investments in research and development, infrastructure development, and incentive programs support the development and adoption of alternative propulsion technologies, driving market growth and innovation in the propulsion system sector.

Additionally, market demand for propulsion systems is driven by factors such as industry trends, market dynamics, and customer preferences. In the aerospace industry, for example, there is a growing demand for more fuel-efficient and environmentally friendly propulsion systems to address concerns about carbon emissions and noise pollution. This has led to increased investments in electric and hybrid-electric propulsion technologies for aircraft, drones, and urban air mobility vehicles. In the automotive industry, there is a shift towards electric vehicles (EVs) and hybrid electric vehicles (HEVs) driven by consumer demand for cleaner, greener, and more sustainable transportation options. As a result, automotive manufacturers are investing in electric propulsion systems and battery technologies to meet market demand and comply with regulatory requirements.

Moreover, market factors such as globalization, urbanization, and changing consumer preferences drive innovation and competition in the propulsion system market. Globalization has led to increased competition among propulsion system manufacturers and suppliers, driving market consolidation, partnerships, and strategic alliances to gain market share and expand market presence. Additionally, urbanization trends and changing mobility preferences, such as the rise of shared mobility, autonomous vehicles, and mobility-as-a-service (MaaS) platforms, create new opportunities and challenges for propulsion system providers to develop innovative solutions that cater to evolving transportation needs and preferences. Moreover, advancements in digitalization, connectivity, and data analytics enable propulsion system manufacturers to offer value-added services, such as predictive maintenance, fleet management, and performance optimization, that enhance customer value and differentiate their offerings in the market.

Furthermore, the impact of emerging technologies, such as artificial intelligence (AI), additive manufacturing, and advanced materials, is reshaping the propulsion system market. AI-driven algorithms and predictive analytics enable real-time monitoring, diagnostics, and optimization of propulsion system performance, leading to improved efficiency, reliability, and safety. Additive manufacturing technologies, such as 3D printing, offer new possibilities for lightweight, complex, and customizable propulsion components that optimize performance and reduce manufacturing costs. Additionally, advancements in advanced materials, such as carbon fiber composites, ceramic matrix composites, and lightweight alloys, enable the development of high-performance propulsion systems that offer increased strength, durability, and efficiency while reducing weight and fuel consumption.

Leave a Comment