Top Industry Leaders in the Powder Processing Equipment Market

*Disclaimer: List of key companies in no particular order

Top listed global companies in the industry are:

- Hosokawa Micron Corporation

- Baker Perkins Limited

- Syntegon Technology GmbH

- Hänsel Processing GmbH

- Sollich UK Ltd

- Dongsun Powder Processing Equipment Co. Ltd

- Sanovo Technology Group

- Powder Process-Solutions

- Bepex International LLC

- British Rema

- Classifier Milling Systems

- Powder Systems Corporation

- Charles Ross & Son Company

- Guilin Hongcheng Mining Equipment Manufacture Co. Ltd

- Kemutec, and others.

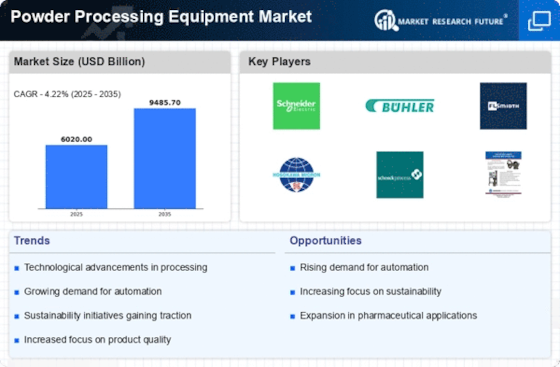

Navigating the Powder Play: Competitive Landscape in Powder Processing Equipment

The powder processing equipment market presents a dynamic arena for established players and innovative disruptors. Understanding the strategies shaping this landscape, the factors governing market share, and emerging trends is crucial for securing a strong position in this evolving marketplace.

Key Players and Strategies:

- Global Giants: Companies like GEA Group and Freudenberg Micron Filtration leverage their extensive product portfolios, research and development capabilities, and established global networks to cater to diverse industries. GEA offers comprehensive solutions for various applications, while Freudenberg focuses on specialized filtration technologies.

- Regional Specialists: Players like Hosokawa Alpine and NETZSCH Group dominate specific geographies by tailoring solutions to regional regulations and industry needs. Hosokawa excels in powder handling equipment for the Asian market, while NETZSCH caters to Europe's stringent pharmaceutical standards.

- Innovation-Driven Startups: Companies like Hosokawa Micron and Quadro Engineering disrupt the market with cutting-edge solutions. Hosokawa Micron focuses on advanced micronization technologies, while Quadro Engineering specializes in high-containment processing equipment.

Factors for Market Share Analysis:

- Technology Leadership: Offering advanced equipment functionalities like micronization, granulation, and coating technologies allows players to address diverse processing needs and attract a wider customer base.

- Industry Expertise: Deep understanding of specific industry regulations and challenges, such as in pharmaceuticals or food processing, enables tailoring solutions for optimal performance and compliance.

- Cost-Effectiveness and ROI: Striking a balance between advanced features and affordability is crucial, especially in price-sensitive segments. Regional specialists like Hosokawa often achieve success with cost-effective options.

- Global Presence and Service Network: Establishing a strong global footprint with readily available parts and after-sales support fosters customer trust and facilitates rapid deployment. GEA's extensive service network exemplifies this advantage.

Emerging Trends and Company Strategies:

- Digitalization and Connectivity: Integrating sensors, data analytics, and cloud platforms into equipment enables real-time performance monitoring, predictive maintenance, and process optimization. Companies like Quadro Engineering are incorporating such smart technologies.

- Focus on Sustainability: Eco-friendly solutions with reduced energy consumption and lower emissions are gaining traction. GEA's energy-efficient dryers address this growing demand.

- Modular and Scalable Systems: Offering modular equipment designs and flexible control systems allows for adaptation to varied production needs and future growth. Hosokawa Micron's modular processing lines cater to this trend.

- Focus on Specialized Applications: Targeting high-growth areas like nanotechnology, additive manufacturing, and battery production with specialized equipment presents lucrative opportunities. NETZSCH's solutions for battery production exemplify this approach.

Overall Competitive Scenario:

The powder processing equipment market is a vibrant landscape where established players compete with regional specialists and technology-driven startups. Success hinges on continuous innovation, industry expertise, a global reach, and adapting to emerging trends. Companies embracing digitalization, sustainability, modularity, and specialized solutions hold a strong hand in navigating this dynamic and rewarding market place.

Latest Company Updates:

May 2023

The Desktop Powder Auger Filling Machine, a new product from VTOPS, has just gone on sale. It features a tiny, user-friendly design that makes it the perfect choice for small-scale industrial and laboratory settings.

The Desktop Powder Filling Machine makes use of cutting-edge technology to guarantee accurate and exact powder filling. This degree of accuracy reduces the possibility of product waste brought on by overfilling or underfilling, resulting in cost savings and product quality preservation. The machine's user-friendly interface and simple controls make it simple to use.

February 2023

Syntegon is now extending its Automated Process Development (APD) tool expertise for tablet presses following the launch of the tool for capsule-filling operations in 2020. Pharmaceutical firms have a full solution with the new, automatically adjustable powder feeder and the APD software to choose the best production settings for each product and transfer them with ease to manufacturing equipment.

For use with Syntegon's TPR 200 tablet press, the new powder feeding mechanism was designed specifically. To match any stirrer setup, the system may be automatically modified. To reflect aspects like the impact of powder movement on tablet characteristics, the impellers feature a square and a round side. Also adjustable are the stirrer blades' inclination, rotational speed, and direction.

The APD tool analyses the functional relationships between material attributes, process factors, and crucial quality features of the finished product. It is based on the Design of Experiments (DoE). Employing a properly defined database, enables pharmaceutical producers to faithfully recreate the production environment and establish dependable parameters.