Expansion in Construction Sector

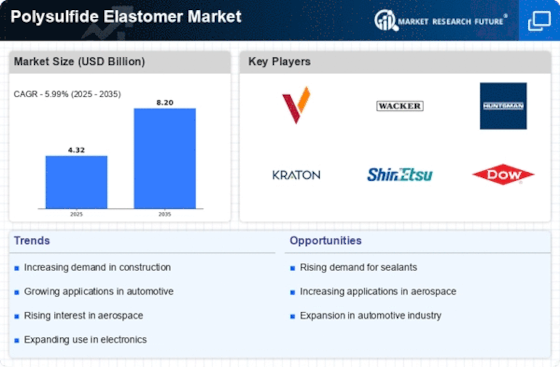

The Polysulfide Elastomer Market is poised for growth, particularly due to the expansion of the construction sector. Polysulfide elastomers are increasingly employed in construction applications, such as sealants and coatings, which provide excellent adhesion and flexibility. The construction industry is witnessing a resurgence, with numerous infrastructure projects underway, leading to heightened demand for durable and weather-resistant materials. In 2025, the construction sector is expected to significantly contribute to the polysulfide elastomer market, as builders and contractors seek materials that enhance structural integrity and longevity. This trend suggests a favorable outlook for polysulfide elastomers, as they align with the industry's requirements for high-performance materials.

Rising Demand in Automotive Applications

The Polysulfide Elastomer Market experiences a notable surge in demand due to its extensive applications in the automotive sector. These elastomers are utilized in manufacturing seals, gaskets, and adhesives, which are essential for ensuring vehicle durability and performance. As automotive manufacturers increasingly focus on enhancing vehicle efficiency and longevity, the demand for high-performance materials like polysulfide elastomers is likely to rise. In 2025, the automotive sector is projected to account for a significant share of the polysulfide elastomer market, driven by the need for lightweight and resilient materials that can withstand harsh environmental conditions. This trend indicates a robust growth trajectory for the polysulfide elastomer market, as automotive innovations continue to evolve.

Technological Innovations in Material Science

Technological advancements in material science are driving the evolution of the Polysulfide Elastomer Market. Innovations in polymer chemistry and processing techniques are enhancing the performance characteristics of polysulfide elastomers, making them more versatile and effective in various applications. These advancements enable the development of elastomers with improved thermal stability, chemical resistance, and mechanical properties. As industries increasingly adopt these enhanced materials, the polysulfide elastomer market is likely to witness a significant uptick in demand. In 2025, the impact of these technological innovations is expected to be profound, as manufacturers leverage new formulations to meet the evolving needs of diverse sectors.

Increased Investment in Research and Development

The Polysulfide Elastomer Market is experiencing a boost due to increased investment in research and development (R&D) activities. Companies are allocating substantial resources to explore new formulations and applications for polysulfide elastomers, aiming to enhance their performance and expand their market reach. This focus on R&D is likely to yield innovative products that cater to the specific needs of various industries, including aerospace, automotive, and construction. In 2025, the impact of these investments is expected to be significant, as new developments may lead to the introduction of advanced polysulfide elastomers that offer superior properties. This trend indicates a proactive approach within the industry, fostering growth and competitiveness.

Growing Awareness of Environmental Sustainability

The Polysulfide Elastomer Market is influenced by the growing awareness of environmental sustainability among consumers and manufacturers alike. As industries strive to reduce their carbon footprint, there is a shift towards using eco-friendly materials, including polysulfide elastomers that can be formulated to meet sustainability criteria. This trend is particularly evident in sectors such as construction and automotive, where the demand for sustainable solutions is on the rise. In 2025, the polysulfide elastomer market is likely to benefit from this shift, as manufacturers increasingly focus on developing products that align with environmental standards. This growing emphasis on sustainability may drive innovation and open new avenues for market growth.