Top Industry Leaders in the Platinum Palladium Carbon Catalyst Market

Platinum and palladium carbon catalysts, the invisible conductors orchestrating countless chemical reactions, play a crucial role in powering our world. From refining petroleum to synthesizing pharmaceuticals, these finely dispersed precious metals on activated carbon dance within reactors, accelerating and directing vital processes. we'll delve into the intricate tapestry of the platinum and palladium carbon catalyst market, examining the factors influencing market share, the strategies adopted by key players, industry news shaping the future.

Market Share: A Balancing Act on a Microscopic Stage

Several crucial factors determine who dictates the tempo in this dynamic market:

-

Metal Choice: Platinum generally enjoys broader application, while palladium shines in specific reactions like hydrogenation. Cost fluctuations of the precious metals significantly impact market dynamics. -

Application Scope: The market spans diverse segments like petroleum refining, fine chemicals, pharmaceuticals, hydrogenation processes, and environmental applications. Each segment has its own catalyst requirements and market dynamics. -

Geographical Distribution: Asia Pacific leads the charge, driven by rapid industrialization and a burgeoning chemical industry. However, Europe and North America remain significant players, with mature markets and high demand for specialized catalysts. -

Catalyst Performance: Factors like activity, selectivity, and stability influence the value proposition of a catalyst. Manufacturers constantly innovate to deliver enhanced performance and cater to specific needs. -

Player Strategies: From established chemical giants like BASF and Johnson Matthey to niche players specializing in custom catalyst design, the market boasts a diverse range of competitors. Their strategies range from product diversification and technological advancements to strategic partnerships and sustainability initiatives.

Strategic Maneuvers: Securing a Foothold in the Catalyst Battlefield

Players in the platinum and palladium carbon catalyst market are wielding their expertise to claim their share:

-

Product Innovation: Developing new catalyst formulations with improved activity, selectivity, and lifespan extends their applicability and differentiates players from the competition. -

Sustainability Focus: Highlighting the recyclability of precious metals and the development of eco-friendly catalyst supports resonates with environmentally conscious consumers and aligns with green regulations. -

Technological Advancements: Implementing advanced synthesis and characterization techniques leads to more efficient catalyst production, reduces waste, and unlocks new avenues for performance optimization. -

Market Expansion: Entering new geographical markets or expanding existing footprints in high-growth regions like Southeast Asia and Latin America fuels market share growth. -

Strategic Partnerships: Collaborating with raw material suppliers, research institutions, and application-specific industries fosters innovation and opens up new avenues for product development and market reach.

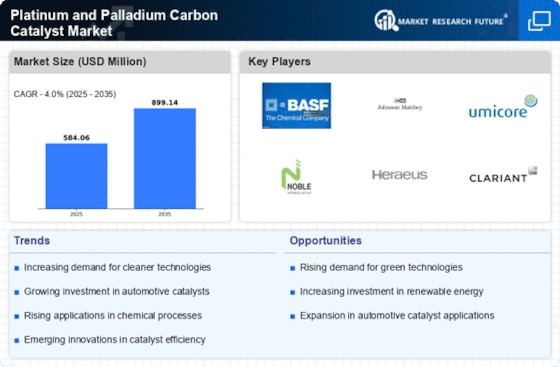

Key Players:

Johnson Matthey (UK), Evonik Industries AG (Germany), BASF AG (Germany), Clariant AG (Switzerland), Vineeth Precious Catalysts Pvt. Ltd (India), Sabin Metal Corporation (US), FUJIFILM Wako Pure Chemical Corporation (Japan), American Elements (US), Chimet S.p.A. (Italy), Heraeus Group (UK), Alfa Aesar (US), Shaanxi Kaida Chemical Engineering Co., Ltd (China), Shanxi Kaida Chemical (China), KaiDa Chemicals (China), and Umicore N.V. (Belgium).

Recent Developments:

July: The International Council of Chemical and Petroleum Industries (ICCP) releases a report highlighting the crucial role of platinum and palladium carbon catalysts in achieving cleaner and more efficient chemical production.

August: Johnson Matthey, a leading catalyst manufacturer, announces plans to invest in a new production facility in India to cater to the rising demand in the Asian market.

September: The European Commission proposes a new regulation restricting the use of certain harmful chemicals found in traditional catalyst supports, paving the way for wider adoption of sustainable alternatives.

October: Researchers at Stanford develop a new type of catalyst using palladium nanoparticles encapsulated in bio-derived polymers, offering enhanced activity and recyclability.

November: A consortium of leading chemical companies launches a joint initiative to develop standardized recycling protocols for spent platinum and palladium catalysts, boosting resource efficiency.

December: BASF unveils a new line of platinum and palladium carbon catalysts specifically designed for hydrogen production from renewable sources, contributing to the green hydrogen revolution.