Growth in the Beverage Industry

The beverage industry is experiencing robust growth, which significantly influences the Plastic Blow Molding Machine Market. With the rising consumption of bottled beverages, including water, soft drinks, and alcoholic beverages, the need for efficient and high-capacity blow molding machines is becoming increasingly critical. Recent statistics indicate that the beverage packaging segment is expected to account for over 30% of the total market share in the coming years. This growth is prompting manufacturers to innovate and enhance their production capabilities, ensuring that they can meet the escalating demand for high-quality, durable plastic containers.

Expansion of the Automotive Sector

The expansion of the automotive sector is contributing to the growth of the Plastic Blow Molding Machine Market. As automotive manufacturers increasingly utilize plastic components for lightweighting and design flexibility, the demand for blow molded parts is on the rise. This trend is particularly evident in the production of fuel tanks, interior components, and exterior body parts. Recent data indicates that the automotive plastics market is projected to grow at a CAGR of approximately 6% over the next five years. Consequently, this growth is likely to drive demand for advanced blow molding machines capable of producing high-quality automotive parts, thereby enhancing the overall market landscape.

Increasing Environmental Regulations

The rise in environmental regulations is a significant driver for the Plastic Blow Molding Machine Market. Governments worldwide are implementing stricter regulations regarding plastic usage and waste management, compelling manufacturers to adopt more sustainable practices. This shift is leading to an increased demand for machines that can produce recyclable and biodegradable plastic products. As a result, manufacturers are investing in research and development to create machines that align with these regulations. The market for eco-friendly blow molding machines is expected to expand, potentially reaching a valuation of several billion dollars in the next few years, as companies strive to comply with environmental standards.

Rising Demand for Lightweight Packaging

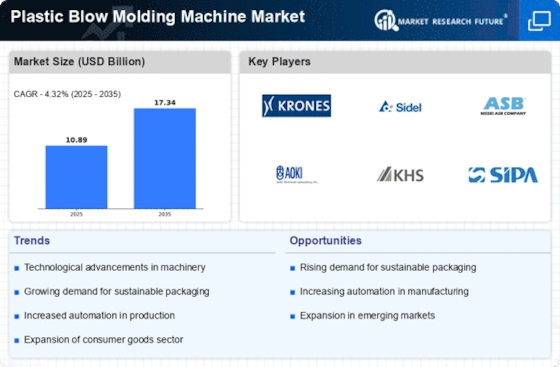

The increasing demand for lightweight packaging solutions is a primary driver for the Plastic Blow Molding Machine Market. As consumers and manufacturers seek to reduce shipping costs and improve fuel efficiency, lightweight materials have gained prominence. This trend is particularly evident in sectors such as food and beverage, where companies are transitioning to lighter packaging options. According to industry reports, the demand for lightweight packaging is projected to grow at a compound annual growth rate of approximately 4.5% over the next five years. Consequently, manufacturers of plastic blow molding machines are adapting their technologies to meet this demand, thereby enhancing their market presence and competitiveness.

Technological Innovations in Manufacturing

Technological innovations are reshaping the Plastic Blow Molding Machine Market, driving efficiency and productivity. Advanced automation, robotics, and smart manufacturing technologies are being integrated into blow molding processes, allowing for greater precision and reduced production times. These innovations not only enhance the quality of the final products but also lower operational costs. As manufacturers increasingly adopt these technologies, the market is likely to witness a surge in demand for state-of-the-art blow molding machines. Industry expert's suggest that the adoption of such technologies could lead to a market growth rate of around 5% annually, reflecting the industry's shift towards modernization.