Sustainability Initiatives

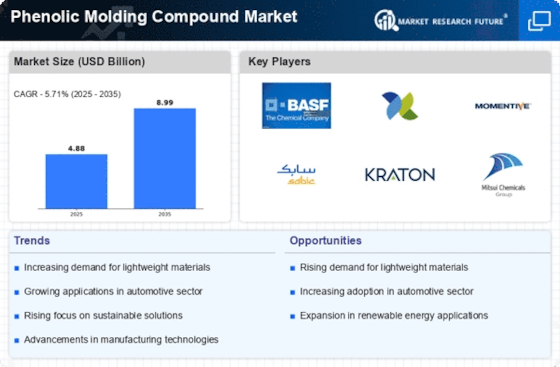

The increasing emphasis on sustainability initiatives is a pivotal driver for the Phenolic Molding Compound Market. Manufacturers are increasingly adopting eco-friendly practices, which include the use of phenolic compounds that are recyclable and have a lower environmental impact. This shift is driven by regulatory pressures and consumer demand for sustainable products. As a result, companies are investing in research and development to create phenolic molding compounds that meet these sustainability criteria. The market is projected to witness a compound annual growth rate (CAGR) of approximately 5% over the next few years, as more industries seek to align with environmental standards. This trend not only enhances the market's growth potential but also encourages innovation in product formulations, thereby expanding the application scope of phenolic molding compounds.

Technological Advancements

Technological advancements play a crucial role in shaping the Phenolic Molding Compound Market. Innovations in manufacturing processes, such as improved molding techniques and enhanced curing methods, are enabling the production of high-performance phenolic compounds. These advancements lead to better mechanical properties, thermal stability, and chemical resistance, making phenolic molding compounds more appealing for various applications. The integration of automation and smart technologies in production lines is also streamlining operations, reducing costs, and increasing efficiency. As a result, the market is expected to grow steadily, with a projected increase in demand from sectors such as automotive and aerospace, where high-performance materials are essential. The ongoing research into new formulations and applications further indicates a robust future for the phenolic molding compound market.

Rising Demand in Electronics

The rising demand in the electronics sector is significantly influencing the Phenolic Molding Compound Market. With the proliferation of electronic devices, there is an increasing need for materials that offer excellent electrical insulation and thermal stability. Phenolic molding compounds are well-suited for these applications due to their superior dielectric properties and resistance to heat. The market for phenolic compounds in electronics is anticipated to grow at a CAGR of around 6% as manufacturers seek reliable materials for circuit boards, connectors, and other components. This trend is further supported by the ongoing miniaturization of electronic devices, which necessitates the use of compact and efficient materials. Consequently, the phenolic molding compound market is likely to expand as it meets the evolving needs of the electronics industry.

Expansion in Construction Sector

The expansion in the construction sector is emerging as a vital driver for the Phenolic Molding Compound Market. As urbanization accelerates and infrastructure projects proliferate, there is a growing demand for materials that offer durability and resistance to environmental factors. Phenolic molding compounds are increasingly being utilized in construction applications, such as insulation panels, flooring, and decorative elements, due to their excellent mechanical properties and aesthetic versatility. The construction industry is expected to grow at a steady pace, with investments in residential and commercial projects driving the need for high-performance materials. This trend suggests a promising outlook for the phenolic molding compound market, as it aligns with the evolving requirements of the construction sector, particularly in terms of sustainability and energy efficiency.

Growth in Automotive Applications

The growth in automotive applications is a significant driver for the Phenolic Molding Compound Market. As the automotive sector increasingly focuses on lightweight materials to enhance fuel efficiency and reduce emissions, phenolic molding compounds are gaining traction. These materials offer a unique combination of strength, durability, and heat resistance, making them ideal for various automotive components, including interior parts and electrical housings. The automotive industry is projected to witness a steady growth rate, with an increasing shift towards electric vehicles (EVs) that require advanced materials for battery enclosures and other components. This transition is likely to bolster the demand for phenolic molding compounds, as manufacturers seek materials that can withstand the rigors of modern automotive applications while contributing to overall vehicle performance.