Market Trends

Key Emerging Trends in the Pharmaceutical Robots Market

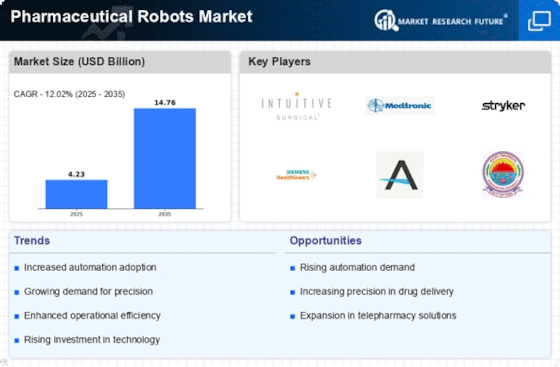

The market of the pharmaceutical robots has manifested trends which are beyond imagination and have made an immense influence of automation and robotics on the pharmaceutical industry. One significant trend is the proliferation of robotics in pharmaceutical manufacturing plants. Also, it is worth noting. Robots are being used for many tasks: dispensing drugs, sorting, packaging, and sometimes even for inspection. Automation using pharmaceutical robots has many benefits to offer in the realm of production processes. These efficiency gains have led to greater precision and reliability, thereby greatly reducing errors and errors and boosting the quality of manufacturing processes. This tendency as a whole reflects the fact that the automatic production in the pharmaceutical manufacturing is increasing in order to reach the general target of the superior quality and the high efficiency.

Shared humanoid robots, or cobots, have become a major emphasis in the market of Pharmaceutical robots, where they play an important role. Different from typical industrial robots which are built to work independently from human operators, cobots are purpose-built for co-operation with humans and therefore including a friendly and innovative production facility as an outcome. In pharapeutical environments cobots work in collaboration with humans for tasks that require human-machine interaction such as intricate assembly or handling of fragile material. Cobots being integrated help in increasing operation flexibility, improve the safety situation and give the possibility to use the synergy of human capabilities and robot capabilities effectively.

The late 20th century witnessed almost 800 million people migrating either internally or across borders while escaping from disastrous consequences of conflicts and natural disasters. Humanized Automation of laboratories through robotics is the key that opens the acceleration of high-throughput screening, sample preparation, and analysis of data, which set the speed of drug discovery pipelines. This trend demonstrates a progressively growing acceptance of the realizing importance of robotics in evaluating of pharmaceutical research and development work, which results in constant speed of taking new drugs intended for patients.

Pharmaceutical compounding ritual has evolved due to greater demand for personalized medicine (including small-volume production) and functions of automation such as robotic systems are more than ever used. A robotic compounding system can prepare individualized drugs risk free with high accuracy, whereas the major source of risk associated with manual compounding is error. This development goes accordingly with the efforts in the industry to cater to the growing and fast changing demands of the patients through innovated pharmaceutical products.

AI and ML technology are becoming more ubiquitous with pharmaceutical robots, which is one of the other trends to watch for. Robots with the help of AI systems that can be programmed with algorithms and are able to do multiple tasks more efficiently than machine operators can would be the answer to the growing need for the ever-changing in manufacturing processes. Along with this, such developments increase the autonomy of pharmaceutical robots and optimize predictive maintenance processes by minimizing downtimes while the interpretation of different parameters ensure continuous operational efficiency.

Leave a Comment