Pharmaceutical Hdpe Bottles Size

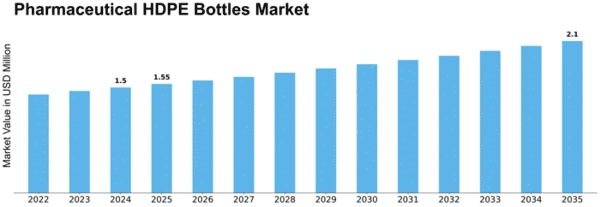

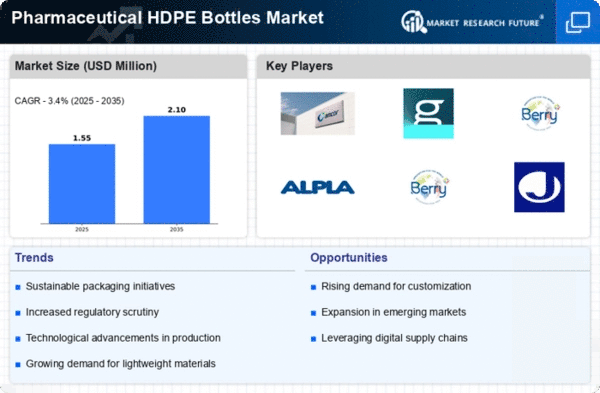

Pharmaceutical HDPE Bottles Market Growth Projections and Opportunities

The market for pharmaceutical HDPE (High-Density Polyethylene) bottles is influenced by various factors that shape its dynamics within the packaging industry. One critical factor is the regulatory environment, as pharmaceutical packaging is subject to stringent guidelines to ensure product safety and efficacy. Pharmaceutical HDPE bottles are favored for their chemical resistance, durability, and ability to protect medications from external contaminants. Compliance with regulatory standards is paramount in the pharmaceutical industry, and manufacturers of HDPE bottles must adhere to specific requirements related to material quality, labeling, and child-resistant packaging.

Sustainability is emerging as a significant driver in the pharmaceutical HDPE bottles market. With a growing focus on environmental responsibility, pharmaceutical companies are increasingly seeking packaging solutions that are recyclable and eco-friendly. HDPE, being a recyclable plastic, aligns with this sustainability trend. Pharmaceutical HDPE bottles are favored for their ability to be recycled, reducing the environmental impact associated with single-use packaging. The adoption of sustainable packaging practices is not only driven by regulatory considerations but also by the changing preferences of environmentally conscious consumers and businesses.

Economic factors play a crucial role in the pharmaceutical HDPE bottles market. Economic conditions, healthcare spending, and pharmaceutical manufacturing activities impact the demand for packaging materials. As healthcare infrastructure develops and pharmaceutical production increases, there is a corresponding rise in the need for reliable and cost-effective packaging solutions. Conversely, economic downturns or fluctuations in healthcare budgets may influence the demand for pharmaceutical HDPE bottles. Manufacturers and stakeholders in the industry must closely monitor economic trends to adapt to market dynamics effectively.

Technological advancements contribute to innovation in the pharmaceutical HDPE bottles market. Continuous improvements in blow molding technologies, barrier coatings, and printing techniques enhance the functionality, safety features, and visual appeal of HDPE bottles. Advanced manufacturing processes allow for the production of bottles with precise specifications, ensuring compatibility with different types of medications. Additionally, innovations in tamper-evident closures and child-resistant packaging technologies enhance the security and integrity of pharmaceutical products, meeting the evolving needs of the industry.

Consumer safety and product integrity are paramount considerations in the pharmaceutical HDPE bottles market. The inherent properties of HDPE, such as its resistance to moisture, chemicals, and UV radiation, contribute to the protection of pharmaceutical products from external factors that could compromise their efficacy. The design and features of HDPE bottles, including tamper-evident seals and child-resistant closures, are essential in ensuring the safety of consumers and the integrity of the medications they contain. As consumer awareness of these safety features increases, pharmaceutical companies prioritize the use of HDPE bottles for their packaging needs.

Market competition in the pharmaceutical HDPE bottles industry is influenced by factors such as pricing, quality, and compliance with industry standards. Competitive pricing strategies that consider production costs, raw material prices, and market demand impact a company's market position. Building a reputation for producing high-quality, compliant, and reliable HDPE bottles is crucial for attracting and retaining pharmaceutical clients. Effective communication and collaboration with regulatory bodies further contribute to market credibility. Manufacturers and distributors must navigate these competitive factors strategically to establish a strong presence in the pharmaceutical HDPE bottles market.

Leave a Comment