Pet Bottle Recycling Size

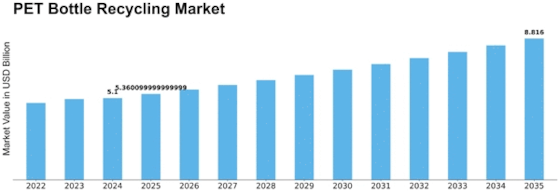

PET Bottle Recycling Market Growth Projections and Opportunities

The PET bottle recycling market is influenced by a myriad of market factors that play a pivotal role in shaping its dynamics. These elements collectively influence the market growth and sustainability that corresponds with growing global attention to environmental protection. It should be noted that heightened awareness of environmental issues increased focus on sustainable practises, igniting the demand for PET bottle recycling. Strong government regulations and policies worldwide, focused on decreasing the generation of plastic waste and encouraging recycling are major market proponents. The preference of consumers changes and more focus is put on the environmental nature of products, which promotes recycled PET bottles. As more consumers acknowledge the impact of single-use plastics on the environment, they gradually adopt alternatives made from recycled material. The PET bottle recycling processes become more efficient and cost-effective due to the constant innovations of technologies in this field. Market development is further increased through innovations in sorting, cleaning and processing technologies leading to higher quality recycled PET. The idea of circular economy, where materials are recycled and reused is adopted leading to the investment in PET bottle recycling infrastructure. Companies and governments that adhere to circular economy principles create favorable conditions for the development of the PET bottle recycling market. There are also varying consumer spending habits as a result of economic conditions or situations which in turn could either increase the demand for recycled PET products. Market growth is possible through economic incentives, subsidies and government support of recycling programs. Volatility in raw material prices may impact the cost dynamics of PET bottle recycling, consequently shaping market trends. In order for PET bottle recycling to grow, adequate recycling infrastructure that includes collection systems and the facilities necessary for undertaking such activities should be put in place. Market growth largely depends on investments of governments and private organizations in the development of infrastructure. The interactions between various stakeholders such as recyclers, manufacturers and government bodies help to build a strong ecosystem of recycle. Agreements between supply chain companies create opportunities for recycled PET materials to be efficiently gathered, processed and reused. More and more brands are embracing sustainability in their corporate plans, using recycled PET for packaging to strengthen the idea that they have an environmental-friendly look. Demand for Recycled PET Products is positively related to consumer preference towards brands possessing strong sustainability initiatives. The interconnectedness of global supply chains influences the availability and distribution of recycled PET products. Trade dynamics, geopolitical factors, and logistics play a role in shaping the global PET bottle recycling market.

Leave a Comment