North America Textile Coatings Size

North America Textile Coatings Market Growth Projections and Opportunities

The North American Textile Coatings Market’s dynamics and growth are influenced by many factors. This is a market driven by functional textiles in different fields entailing the demand for use. As consumers seek fabric with water resistance, flame resistance and antibacterial properties, the call for textile coating has increased. For outdoor wear or industrial protective equipment, textile coatings make fabrics more practical and durable.

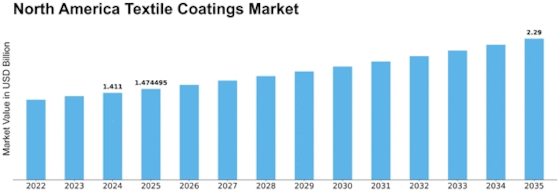

The size of the North American Textile Coatings Market was USD 1.3 Billion in 2022. A CAGR of 4.50% expects the textile coatings business to rise from USD 1.35 Billion in 2023 to USD 1.931 Billion in 2032.

North America Textile Coatings Market is shaped by advances in coating technology. Through continuous research and development, advanced coating formulas that enhance performance without sacrificing textile comfort and breathability are developed. In this region, nanotechnology-based coatings, phase change materials, and conductive coatings for smart textiles have boosted textile coating applications.

North American textile coatings markets are influenced by environmental sustainability as well. Consumers as well as manufacturers prefer waterborne, solventless or low VOC (volatile organic compound) based coatings which enhance sustainability of products manufactured. To meet the requirements of customers who care about ecology, these technologies include bio-based coats as well as recycled materials used on textiles.

Market variables come under textual coating regulations and standards alike.Their compliance to chemical safety environmental requirements among others is required for all North America Textile Coatings Market manufacturers and suppliers.Therefore,this ensures safety of users while enhancing credibility of products manufactured through use of such substances.

Covid-19 pandemic has affected consumer behavior just like it has corporate interests.Due to hygiene & health safety awareness there is a high demand for textiles having antimicrobial & antiviral treatments.This move leads to diversification in nursing home industry thus affecting healthcare ,hospitality industry & apparel manufacturing sectors as well.

North American textile coatings markets are influenced by economic factors as well as industry partnerships. Some of the major factors affecting demand for coated textiles include economic growth, consumer spending and health of the automotive, healthcare and construction industries. Coating manufacturers, textile manufacturers and end-users collaborate to innovate and provide industry-specific coating solutions.

The North America Textile Coatings Market is also affected by competitive landscape and branding tactics. To make their product appear different, companies brand, promote and highlight unique features exhibited. A company may build its market position by offering protective coatings for workwear or water repellent coatings for outdoor fabrics.

Leave a Comment