Growth in Automotive Sector

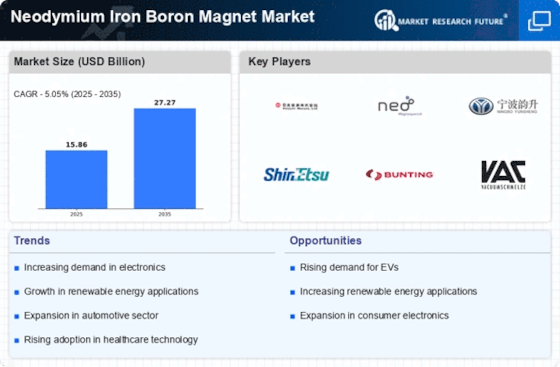

The automotive industry is a key driver for the Neodymium Iron Boron Magnet Market, particularly with the rise of electric vehicles (EVs). As automakers increasingly adopt electric drivetrains, the demand for high-performance magnets has escalated. Neodymium iron boron magnets are essential in electric motors, which are crucial for the operation of EVs. The Neodymium Iron Boron Magnet Market is anticipated to expand rapidly, with projections indicating that EV sales could reach 30% of total vehicle sales by 2030. This shift towards electrification in the automotive sector is likely to bolster the Neodymium Iron Boron Magnet Market, as manufacturers require efficient and powerful magnets to meet the performance demands of modern vehicles.

Rising Demand in Medical Devices

The Neodymium Iron Boron Magnet Market is also witnessing growth due to the rising demand for advanced medical devices. These magnets are utilized in various applications, including MRI machines and other diagnostic equipment, where strong magnetic fields are essential. The healthcare sector is increasingly adopting innovative technologies, leading to a surge in the production of sophisticated medical devices. Market data indicates that the medical device market is expected to grow at a compound annual growth rate of approximately 7% over the next few years. This trend is likely to enhance the demand for neodymium iron boron magnets, as manufacturers seek to incorporate high-performance components to improve diagnostic accuracy and patient outcomes.

Increasing Applications in Electronics

The Neodymium Iron Boron Magnet Market is experiencing a surge in demand due to the increasing applications of these magnets in various electronic devices. As consumer electronics continue to evolve, the need for compact and efficient components has become paramount. Neodymium iron boron magnets are integral in the production of smartphones, laptops, and other portable devices, where space and weight are critical factors. The market for these electronics is projected to grow significantly, with estimates suggesting a compound annual growth rate of over 5% in the coming years. This growth in the electronics sector directly influences the Neodymium Iron Boron Magnet Market, as manufacturers seek high-performance magnets to enhance device functionality and efficiency.

Advancements in Renewable Energy Technologies

The Neodymium Iron Boron Magnet Market is significantly influenced by advancements in renewable energy technologies, particularly in wind and solar power generation. Wind turbines utilize these magnets in their generators, enhancing efficiency and power output. As the world increasingly shifts towards sustainable energy sources, the demand for wind energy is projected to grow, with estimates suggesting a doubling of installed capacity by 2030. This growth directly correlates with the need for high-performance magnets, positioning the Neodymium Iron Boron Magnet Market as a critical component in the renewable energy landscape. The integration of these magnets in energy systems not only improves performance but also supports the global transition to cleaner energy solutions.

Technological Innovations in Magnet Production

Technological innovations in the production of neodymium iron boron magnets are driving the Neodymium Iron Boron Magnet Market forward. Advances in manufacturing processes, such as improved sintering techniques and the development of new alloy compositions, are enhancing the performance and reducing the costs of these magnets. As production techniques become more efficient, manufacturers can offer neodymium iron boron magnets at competitive prices, thereby expanding their applications across various industries. The market is likely to benefit from these innovations, as they enable the production of magnets with superior properties, such as higher magnetic strength and better thermal stability. This evolution in manufacturing is expected to play a crucial role in meeting the growing demand across sectors, further solidifying the position of the Neodymium Iron Boron Magnet Market.